Process Parameter Interaction Study for Epoxy/Kenaf Composites Preparation via Two-Level Full Factorial Approach

DOI:

https://doi.org/10.37934/mjcsm.1.1.1126Keywords:

Full Factorial, Interaction Study, Kenaf Fiber, Epoxy, Solution Mixing, High Speed Mechanical Stirrer, OptimizationAbstract

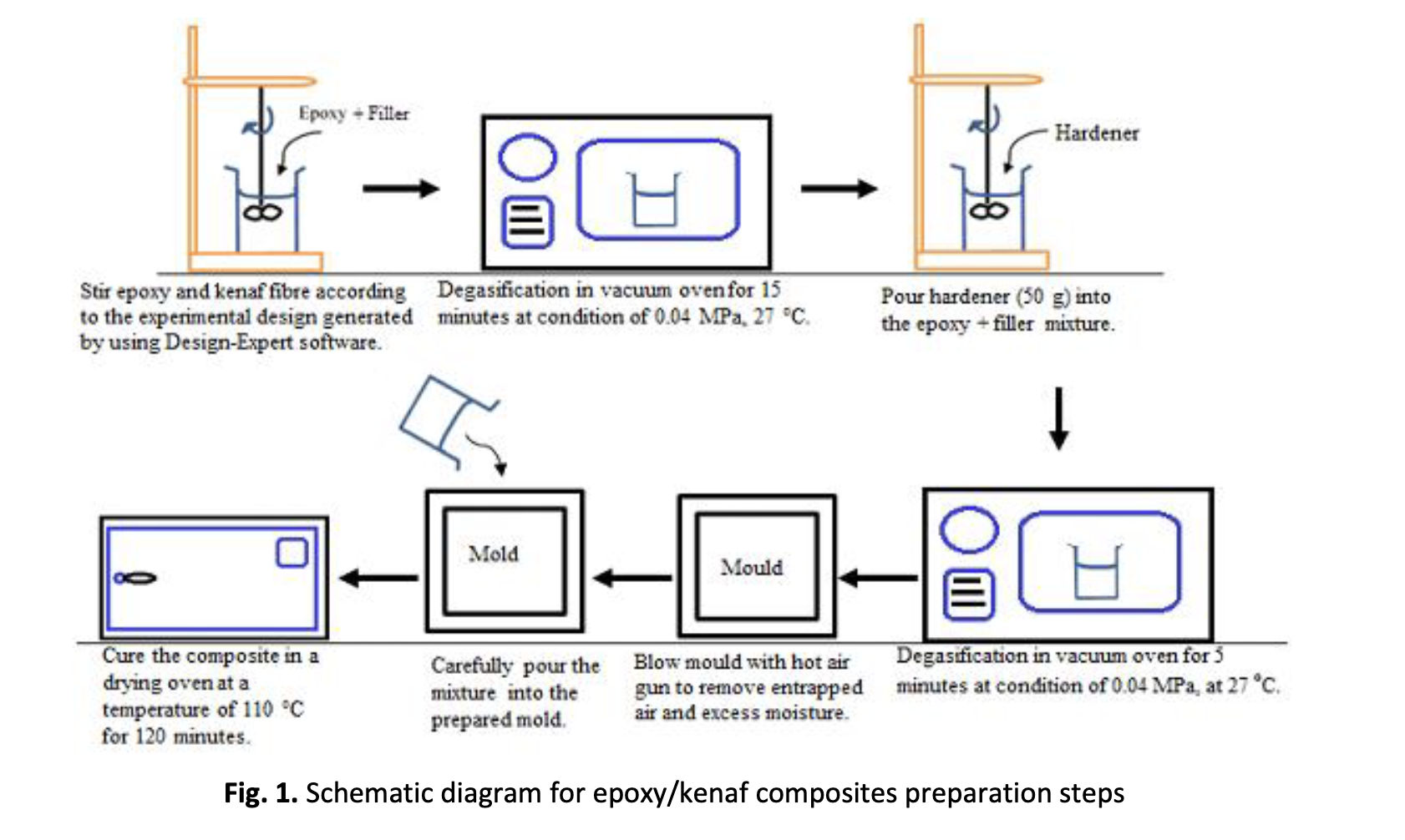

This study was conducted to understand the interaction involved between the process parameters of the solution mixing for the preparation of epoxy/kenaf composites via two-level full factorial approach. There are three (3) independent variables which are the kenaf fibre loadings (-5.00 wt.%; +35.00 wt.%), stirring period (-10.00 mins; +50.00 mins) and the stirring speed (-100 rpm; +700 rpm), involved in this work. A set of 23 full factorial design with three replication at a center point and no block was applied to yield a total of 11 set of experiments. The DesignExpert 6.0.8 statistical software has optimized the resulted tensile strength (TS) response as dependent variable of prepared epoxy/kenaf composites. It was found that the optimum processing parameter are at 100 rpm of stirring speed, 10 mins of the stirring period and about 5.00 wt.% of the kenaf fiber loading, with the highest coeficient of determination R2 value of 99.9%. Fracture surface morphological observation via SEM has been performed to correlate further the interaction between the processing variables toward an optimum resulted TS response. In overall, this study has significance to facilitate manual processing of natural fiber based epoxy composite started at the early integration between the kenaf fiber as reinforcement phase and epoxy as the matrix phase, using a high speed mechanical stirrer apparatus.

Downloads