Enhancement of Mechanical and Electrical Properties in Graphene Nanoplatelet Modified Nylon 66

DOI:

https://doi.org/10.37934/mjcsm.1.1.110Keywords:

Nylon 66, Graphene Nanoplatelets, EMI Shielding, Polymer CompositeAbstract

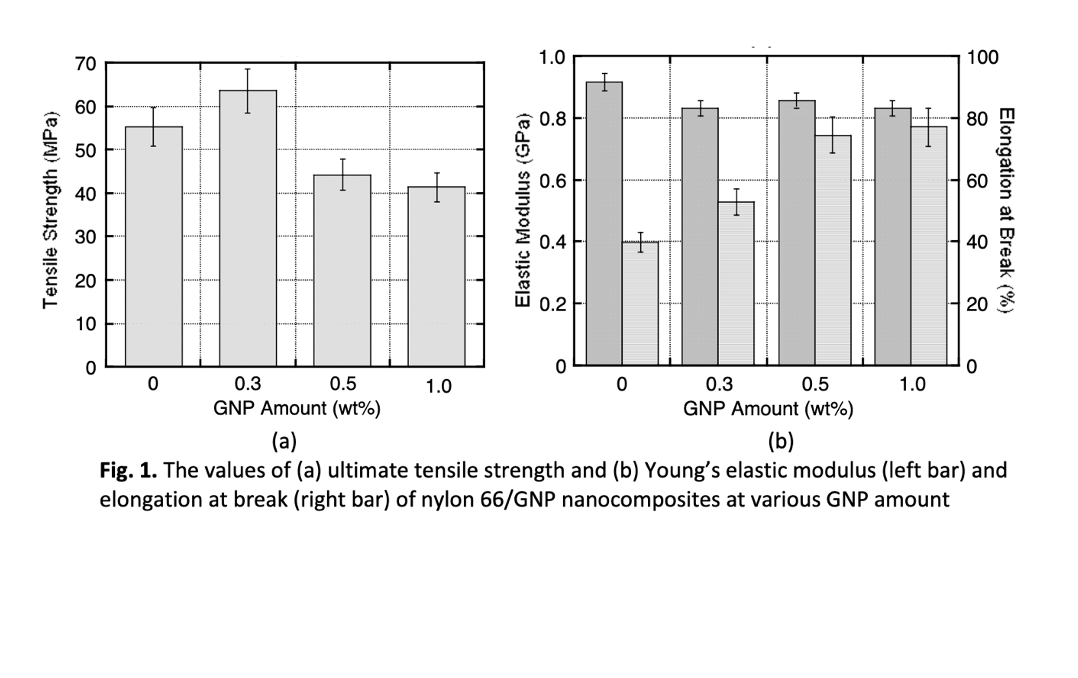

Conventional thermoplastics used in electronic housings and structural members are vulnerable to electromagnetic interference (EMI). To improve the EMI shielding property in thermoplastics, conductive fillers must be incorporated. By using nano-sized conductive fillers such as graphene nanoplatelets (GNP), conductivity can be achieved without the setbacks in terms of cost, processability and mechanical properties. In this study, mechanical and electrical properties of nylon 66 added with a minimal amount of GNP are investigated. Nylon 66/GNP nanocomposites were prepared by dry mixing followed with melt compounding. Sonication was performed prior to the mixing process to reduce agglomeration of GNP. Addition of 0.3 wt% GNP significantly improved (+15.2%) the tensile strength of nylon 66. The increase at 0.3 wt% GNP is attributed to high aspect ratio and good interfacial stress transfer associated with well dispersed GNP. However, tensile strength showed a decrease when GNP amount was further increased to 0.5 and 1.0 wt%. The result is in agreement to the XRD result, in which well dispersion of GNP with no reassembly or re-aggregation of graphene layers in nylon 66 matrix is indicated at 0.3 wt%. The good dispersion level of GNP at 0.3 wt% enables the formation of an effective network for electron path transmittance, as demonstrated by the increase in electrical conductivity.

Downloads