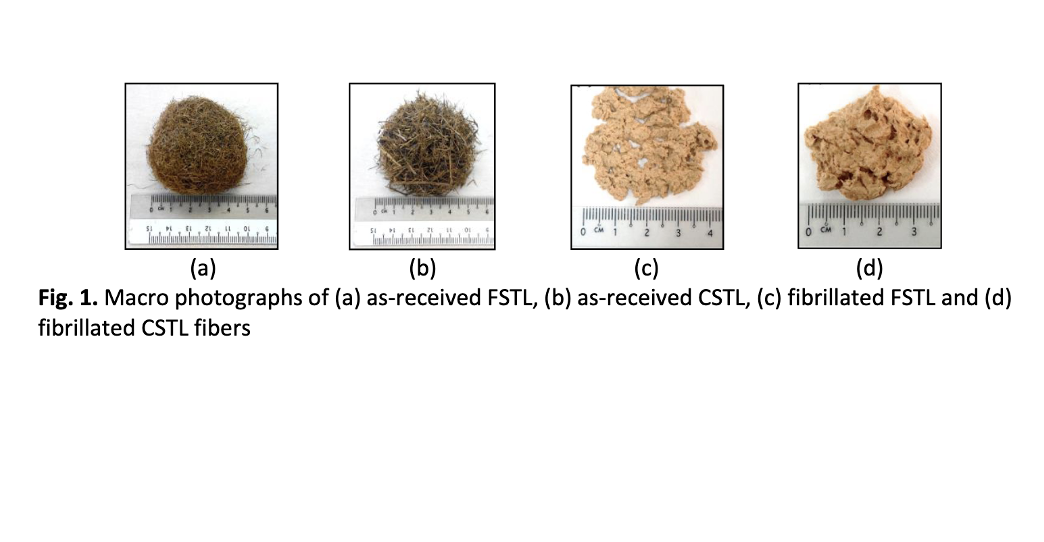

Characterization of Chemomechanical Treated New Fibrillated Cellulosic Nano Fiber from Spent Tea Leaf

DOI:

https://doi.org/10.37934/mjcsm.2.1.111Keywords:

Nano Fibrillation, Spent Tea Leaf, Blending Speed, Cellulose, MorphologyAbstract

This project focuses on the fibrillation of cellulose nano fiber (CNF) derived from spent tea leave (STL) and the characterization of the extracted fibers. STL underwent chemical (NaOH and HCL) pretreatment to degrade the intermolecular bonding between cellulose, hemicellulose and lignin followed by fibrillation at various blending speed and time to isolate the CNF contents mechanically. Vacuum filtering was utilized to filter the fibrillated fibers. The fibrillation effects on the extracted fibers were characterized and analysis by using FTIR, optical and scanning electron microscope. The results indicated that the average diameter of fibrillated fibers were decreased with the concurrent increase of blending speed and time. It was found that blending time and speed in mechanical fibrillation have substantial effect on yielding of nanofibers Fine STL fibers blended at speed and time of 23500 rpm and 10 min provide the smallest NCF diameter (within the range of 20 to 40 nm) along with better fibrillated yield of 15.22% than coarse STL fiber.

Downloads