Mechanical Performance of Recycled Polypropylene Composites Reinforced with Activated Carbon-Treated Clay as Concrete Aggregates

DOI:

https://doi.org/10.37934/mjcsm.16.1.100110Keywords:

Plastic Composite Aggregate, Recycled Polypropylene, Hybrid Filler, Tensile Properties, Plastic Waste, ExtrusionAbstract

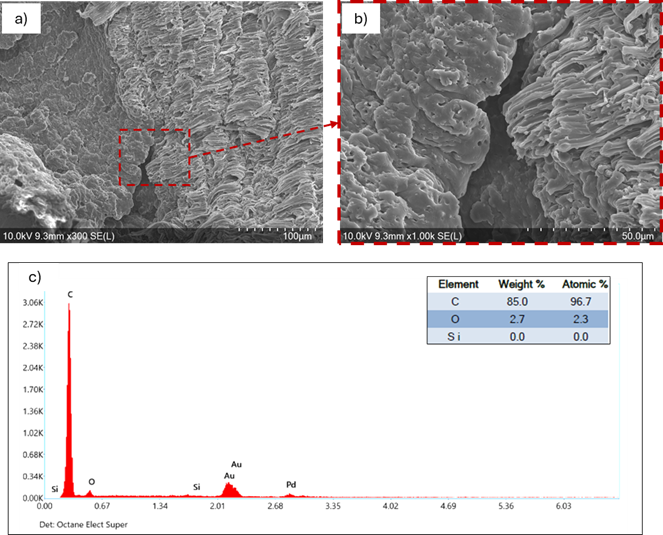

The growing concern over plastic waste and the depletion of natural aggregates has spurred interest in sustainable construction materials. This study examines the mechanical and morphological performance of recycled polypropylene (rPP) composites reinforced with activated carbon (AC)-treated clay for use as lightweight concrete aggregates. The novelty lies in the hybrid filler system combining clay and AC within a recycled polymer matrix; an approach rarely explored for structural concrete applications. Composites were fabricated using a single-screw extruder at 185°C and 50 rpm, incorporating AC at 1, 3, 7, and 15 wt%. Mechanical testing revealed that 3 wt% AC achieved the highest tensile strength due to enhanced filler dispersion and interfacial bonding, while 15 wt% AC increased stiffness but reduced elongation due to agglomeration and brittleness. The highest yield strength at 7 wt% AC suggests a percolation threshold effect, improving load transfer efficiency. FESEM and EDX analyses confirmed better filler distribution and matrix-filler interaction at lower AC contents, aligning with mechanical results. These findings highlight rPP/clay/AC composites as eco-friendly, lightweight concrete aggregate alternatives with a balance of strength, stiffness, and flexibility. This study underscores the environmental benefits of repurposing plastic and carbon-based waste while recommending further investigation into their long-term durability and real-world performance.

Downloads