T6 Heat Treatment Optimization of Thixoformed LM4 Aluminium Alloy using Response Surface Methodology

DOI:

https://doi.org/10.37934/mjcsm.3.1.113Keywords:

Semisolid metal processing, Cooling slope casting, Aluminium alloy, T6 heat treatmentAbstract

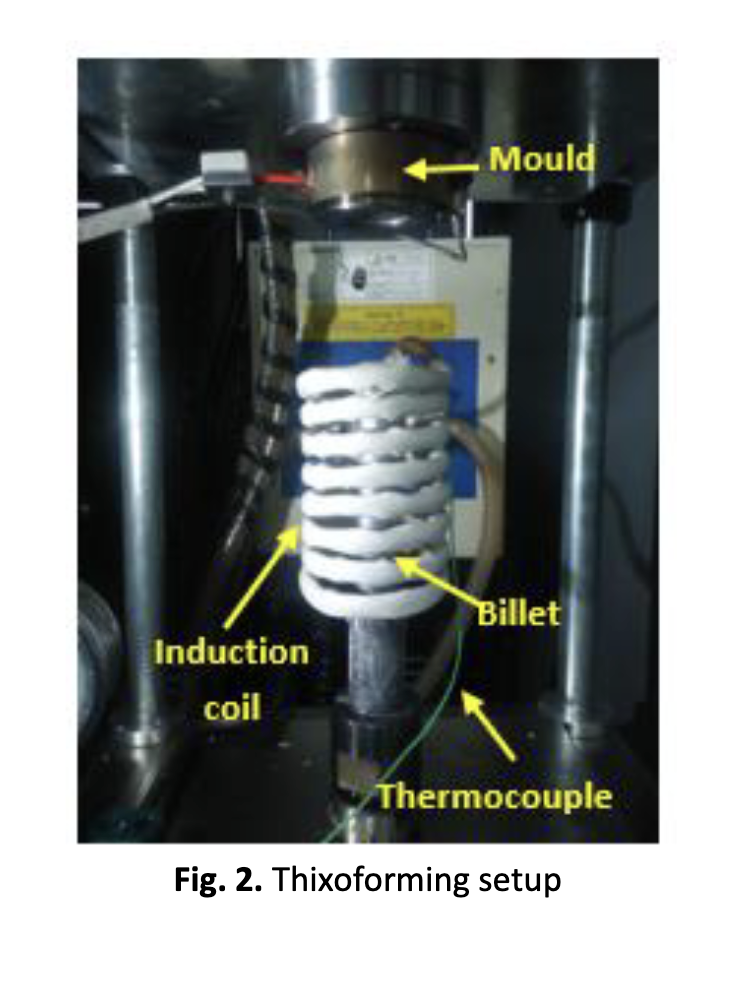

Aluminium alloy of LM4 is abundantly utilized in automotive and aerospace industries because of its good fluidity, high mechanical strength, good wear resistance and low density. T6 heat treatment as part of its forming process will enhanced further these properties. However, the total time required for T6 is very long and often delay the overall production cycle time. Furthermore, thixoforming of semi-solid processing method, which promises a near-net-shape and further enhanced performance of the end products. One of the major concerns is an additional cost in billet feedstock production that slows down the application in industries. Therefore, this paper aim is to optimize the T6 heat treatment on the thixoformed LM4 alloy using response surface methodology (RSM) of Design Expert software. Thus, a simple cooling slope casting to produce the feedstock for thixoforming of near globular and fine ?-Al microstructure is being applied.Cooling slope parameters at pouring temperature of 660 °C; slope length of 440 mm and tilt angle of 45 °. As results, small globular grain size of 35.709 µ and shape factor of 0.89 are obtained. Moreover, based on the RSM responses, the optimum parameters of T6 heat treatment; solution treatment at 530 °C for 30 minutes and 2 hours of ageing at 180 °C. The overall strength of LM4 improved significantly with ultimate tensile strength (UTS) of 252.3 MPa, 98.9 HV surface hardness and coefficient of friction (CoF) of 0.4299, respectively.

Downloads