Physico-Mechanical Behaviors of Chemically Treated Natural Fibers Reinforced Hybrid Polypropylene Composites

DOI:

https://doi.org/10.37934/mjcsm.15.1.2540Keywords:

Coconut Husk, Banana Fiber, Polypropylene, Hybrid Composites, Mechanical PropertiesAbstract

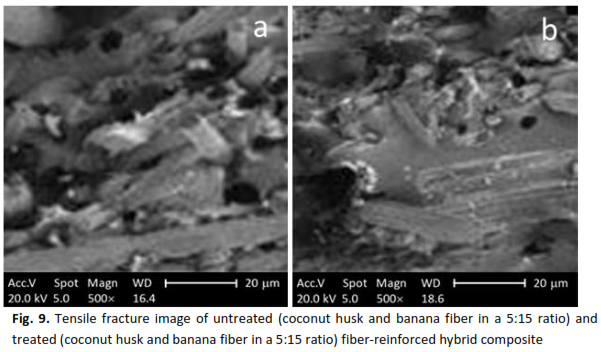

The goal of current research is to replace synthetic materials with natural, biodegradable, and renewable ones. Natural fiber composites are extensively studied due to their unique properties and environmental benefits. These fibers are easily available, easy to handle, and biodegradable. Reinforcing polymers with natural fibers enhances mechanical properties, potentially balancing stiffness, strength, and ductility in hybrid composites. This study assessed the mechanical characteristics of polypropylene reinforced with chopped banana fiber and coconut husk. Investigations were also conducted into the effects of fiber chemical treatment, content, and ratio on mechanical properties. In Bangladesh, two fibers that are commonly available are coconut husk and banana. Raw coconut husk and banana fiber were chemically treated with 5% sodium lauryl sulfate to improve their adhesion with polypropylene. Hot pressing was employed to manufacture the composite using fibers that had been treated with sodium lauryl sulfate (SLS) as well as untreated fibers. The fiber loading was adjusted to be 5, 10, 15, and 20 wt%, while the ratios of coconut husk to banana fibers were modified to be 15/5, 10/10, and 5/15. After that, tests for tensile, flexural, hardness, and water absorption were performed on the created composites. All mechanical parameters increased with increased fiber loading, except for tensile strength. The characteristics of the generated composites were found to be better than those of the polypropylene matrix. The mechanical properties of composites including coconut husk and banana fiber at the 5/15 ratio were superior to those of composites comprising those fibers at the 10/10 or 15/5 ratios. Specifically, the 5/15 ratio composites improved tensile strength, tensile modulus, flexural strength, flexural modulus, and hardness by 11%, 6%, 12%, 24%, and 2%, respectively, compared to the 10/10 ratio composites. Treated fiber composites using SLS-treated coconut husk and banana fiber at the 5/15 ratio showed enhanced mechanical properties compared to untreated composites. These treated composites improved tensile strength, tensile modulus, flexural strength, flexural modulus, and hardness by 17%, 5%, 4%, 1%, and 2%, respectively, over untreated composites. Thus, SLS-treated fiber-reinforced hybrid composites exhibited superior characteristics compared to their untreated counterparts.

Downloads