Numerical Analysis and Experimental Validation of a Smart Wiper Washing System Prototype

Keywords:

Smart wiper system, finite element analysis, spray uniformity, prototype validation, automotive safetyAbstract

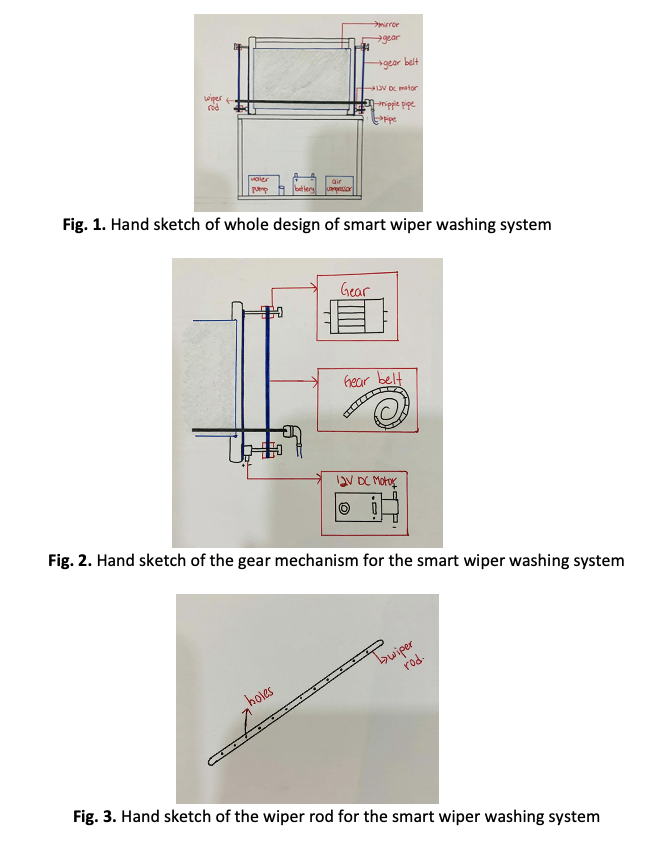

Conventional windshield wiper washer systems often suffer from non-uniform spray coverage, leakage under pressure, and limited structural endurance, reducing their effectiveness in maintaining driver visibility during adverse weather conditions. This study addresses these challenges through the design, structural validation, and experimental testing of a smart wiper washing system prototype. The development process began with conceptual sketches and parametric modeling in SolidWorks, followed by finite element analysis in ANSYS using the von Mises stress criterion to evaluate structural integrity under internal pressurization. The perforated aluminum spray pipe demonstrated negligible deformation (<0.2 mm) and maximum stress values of ~2.25 MPa, well below the material yield strength, confirming a wide safety margin. A physical prototype was fabricated using locally available materials, integrating mechanical, fluidic, and electrical subsystems into a dual-mode actuation cycle: water spraying during the upward stroke and compressed air discharge during the downward stroke. Experimental validation showed spray uniformity above 85% and stable, repeatable wiper motion, with strong agreement between simulation predictions and measured performance. The findings confirm that the proposed system is both structurally robust and functionally reliable, offering a cost-effective and manufacturable solution for enhanced windscreen cleaning. This work contributes to automotive engineering by demonstrating how simulation-driven design can be translated into a validated prototype, providing a practical foundation for future refinement and durability studies.Downloads