Evaluating the Elastic Modulus of Geopolymer Concrete: The Impact of Fly Ash as a Cement Substitute using a No-Soaking Method for Sustainable Construction

DOI:

https://doi.org/10.37934/ard.126.1.5368Keywords:

Geopolymer concrete, fly ash, cement substitution, modulus of elasticity, no-soaking method, sustainable construction, ASTM C469-2, pozzolanic reactionAbstract

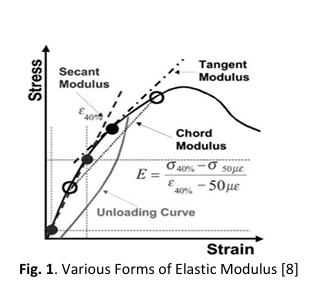

The mechanical properties of concrete play a crucial role in determining its structural performance, particularly its modulus of elasticity, which reflects its deformation resistance under stress. This study investigates the influence of fly ash as a partial cement substitute on the elastic modulus of geopolymer concrete produced using a no-soaking method. Experimental analysis was conducted in accordance with ASTM C469-2, utilizing cylindrical specimens (15 cm in diameter and 30 cm in height) to evaluate the effects of fly ash at replacement levels of 5%, 10%, and 15%. The findings reveal that the incorporation of fly ash significantly influences the elasticity of geopolymer concrete, with measured elastic modulus values of 24.78 MPa, 23.43 MPa, and 21.46 MPa for 5%, 10%, and 15% fly ash substitution, respectively, compared to 20.60 MPa for conventional concrete. The results indicate that a 5% fly ash substitution yields the highest modulus of elasticity, suggesting an optimal balance between pozzolanic reactivity and microstructural densification. However, further increases in fly ash content exhibit a declining trend, potentially due to reduced early-age hydration contributions. This study highlights the potential of fly ash as a sustainable alternative to traditional cement, offering insights into its mechanical performance and implications for eco-friendly construction practices.

Downloads