Design and Development of an Electromagnetic Portable Drill Guide for Improved Precision and Efficiency in DIY Applications

DOI:

https://doi.org/10.37934/ard.126.1.2641Keywords:

Electromagnetic drill guide, precision, technical education, DIY applications, finite element analysisAbstract

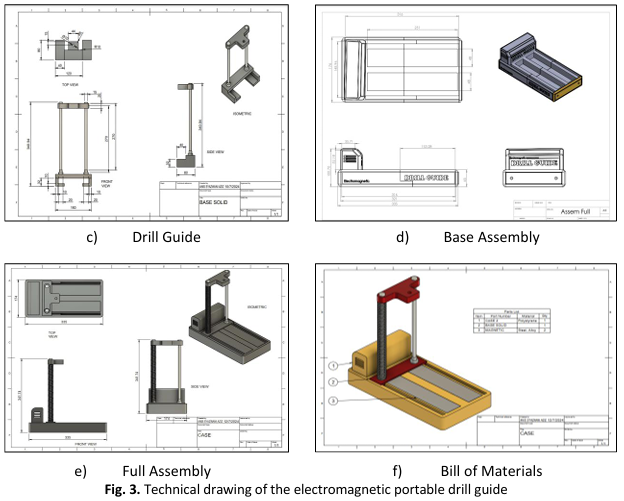

This study investigates the design and performance of an electromagnetic portable drill guide aimed at enhancing precision, efficiency, and sustainability in educational and hobbyist applications. Using a combination of CAD modeling, Finite Element Analysis (FEA), and additive manufacturing, the developed drill guide demonstrated significant improvements in operational precision and portability. Circularity tests on different materials revealed minimal errors, with plywood exhibiting the lowest error rate of 0.40% and sheet metal the highest at 3.2%. FEA simulations confirmed the drill guide's structural integrity, with a maximum von Mises stress of 78.97 MPa (below the yield strength of the material), maximum displacement of 0.18 mm, and a safety factor of 3.48. The prototype, fabricated from mild steel and ABS plastic, was lightweight (5-7 kg) and versatile, supporting a wide range of materials including plywood, acrylic, and sheet metal. These findings highlight the drill guide's potential to improve precision tooling practices while promoting cost-effective and sustainable manufacturing, particularly in educational and DIY settings. Further enhancements are suggested to optimize ergonomic design and extend application versatility.

Downloads