Design and Development of a Universal Magnetic Portable Jig: A Modular Approach for Versatile Clamping Applications

DOI:

https://doi.org/10.37934/ard.125.1.79103Keywords:

Modular jig design, magnetic clamping system, advanced manufacturing techniques, design for assembly (DFA)Abstract

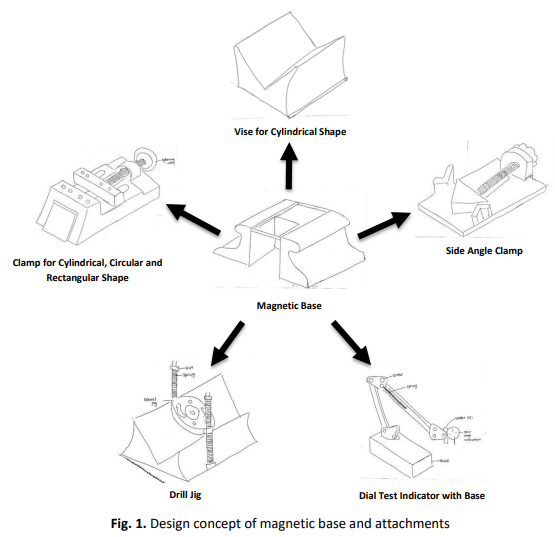

Clamping systems play a crucial role in manufacturing by ensuring precision, stability, and repeatability during machining and assembly operations. However, traditional systems often lack adaptability, portability, and ease of use, particularly for diverse workpiece geometries and dynamic applications. Addressing these limitations, this study aims to develop a Universal Magnetic Portable Jig, designed to provide a versatile and user-friendly clamping solution tailored for educational, DIY, and small-scale industrial contexts. The research utilized advanced manufacturing techniques, including 3D printing, CNC machining, and MIG welding, to create a modular jig with a magnetic base and interchangeable attachments. Comprehensive testing and DFMA analysis were conducted to validate its performance, revealing significant findings. The Vise for Cylindrical Shapes achieved a DFA Index of 112.97, showcasing high efficiency and simplicity, while other attachments, like the Dial Test Indicator Holder, highlighted areas for optimization. Identified limitations, such as reliance on ferromagnetic surfaces and size constraints, provide pathways for further enhancement. This study demonstrates that the Universal Magnetic Portable Jig effectively bridges gaps in traditional clamping systems by offering enhanced adaptability and operational flexibility. The principal results confirm its ability to improve productivity and usability across various applications. Future research will explore scalability for larger workpieces and non-magnetic materials, automation features, and further optimization. The findings establish a strong foundation for innovative clamping solutions in modern manufacturing environments.

Downloads