The Effect of Lean Manufacturing on Production / Operation for the Small and Medium Enterprise in Malaysia

DOI:

https://doi.org/10.37934/ard.121.1.4050Keywords:

Value stream mapping, kanban, why-why analysis, 5S, lead time improvementAbstract

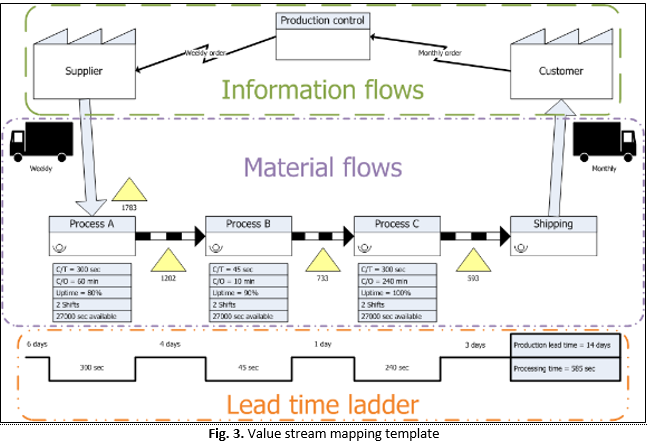

At the start of 2022, the government announced its focus on supporting the development of small and medium enterprises (SMEs) to improve living standards following the COVID-19 pandemic. SMEs contribute significantly to the national economy, with the clothing industry playing a major role. This research applies lean manufacturing techniques to enhance the performance of SMEs in the clothing sector, specifically in T-shirt printing. Therefore the first objective was to collect, analyze processing times and recording of all issues encountered during production. The second objective involved using value stream mapping (VSM) to analyze the T-shirt printing process from raw material supply to finished product packaging. We also employed a why-why analysis to pinpoint the underlying causes of inefficiencies and devise specific solutions. The last objective focused on process improvement using VSM, along with the Kanban system, 5S and Make to Stock (MTS) to optimize block preparation and T-shirt printing. We selected Flexsilk Printshop as the case study. The findings showed a 66.59 % reduction in waiting time, a 30.77 % improvement in lead time, an increase in overall equipment effectiveness (OEE) from 93.3 to 97.45 % and a 50.41 % increase in efficiency.

Downloads