Catalytic Pyrolysis of Malaysia Tea Waste over Molybdenum Modified Zeolite for Bio-Oil Production

DOI:

https://doi.org/10.37934/ard.119.1.3645Keywords:

Tea waste, pyrolysis, catalytic, HZSM-5, molybdenumAbstract

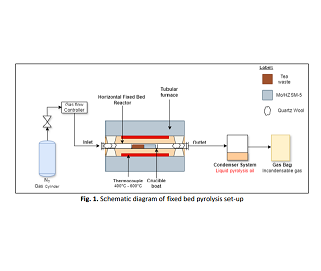

In the current era, the increasing population has raised energy needs and heavy reliance on fossil fuels has led to greenhouse gas emissions. The abundance of biomass in Malaysia, such as tea waste, is poorly managed, contributing to environmental issues. Thus, the main goal of this research is to investigate the influence of Molybdenum-modified Hydrogen-exchanged Zeolite Socony Mobil-5 (Mo-HZSM-5) on the pyrolysis of Malaysian tea waste at varied temperatures from 400 to 600 C with 50 C intervals to produce bio-oil via fixed-bed reactor. The catalyst-to-tea waste mass ratio was constant at 1.1 for all the investigated samples. Among the investigated samples, the highest bio-oil produced was at 600 C (13.97 wt. percent). Surprisingly, adding Mo-HZSM-5 did not increase the bio-oil yield, which is 4.50 wt. percent at 600 C. However, the composition of hydrocarbons in bio-oil from catalytic pyrolysis is higher (18.16 percent) than non-catalytic (9.73 percent) at 500 C. Furthermore, with Mo-HZSM-5, the total oxygenated compound presences are lower (51.77 percent) at 550 C than without catalyst (62.16 percent). Therefore, pyrolysis using Mo-HZSM-5 as a catalyst has proved to increase the amount of hydrocarbon in bio-oil while lighter hydrocarbons were enhanced at lower temperatures (400 C) by the cracking of larger hydrocarbon molecules.

Downloads