Effect of Sodium Chloride-Assisted Heat Treatment on Virgin and Recycled PLA Filaments in FDM 3D Printing

DOI:

https://doi.org/10.37934/mjcsm.16.1.6984Keywords:

PLA, Recycled Filament, Heat Treatment, Mechanical Properties, FDMAbstract

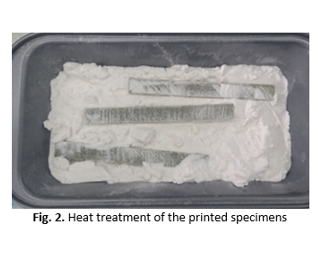

Polylactic acid (PLA) is widely employed in Fused Deposition Modeling (FDM) owing to its biodegradability and ease of processing. Nonetheless, both virgin and recycled forms of PLA exhibit susceptibility to mechanical degradation, particularly under thermal stress. This study investigates the influence of sodium chloride-assisted post-processing heat treatment on the tensile properties of virgin PLA (vPLA), commercial recycled PLA (c-rPLA), and self-extruded recycled PLA (se-rPLA). Sodium chloride, used in the powder bed, helps regulate heat distribution during thermal treatment, improving tensile strength by reducing thermal degradation. Specimens were subjected to thermal treatment in a sodium chloride powder bed at 70°C, 85°C, and 100°C for 90 minutes. Tensile testing, conducted in accordance with ASTM D638, revealed strength improvements ranging from 3–6% for vPLA and 14–18% for c-rPLA. However, a tensile strength reduction of approximately 36% was observed in se-rPLA after heat treatment at 85°C, likely due to thermal sensitivity or material degradation. These findings suggest that while heat treatment can enhance the performance of commercial recycled and virgin PLA, its effectiveness for self-extruded PLA depends heavily on prior processing conditions. The study highlights the importance of carefully tailoring thermal post-processing protocols to the specific characteristics of recycled materials to support their use in sustainable 3D printing.

Downloads