Preparation of Antifouling Composite Coating for Rubber. Part 1: Manufacturing and Laboratory Testing

DOI:

https://doi.org/10.37934/mjcsm.16.1.3545Keywords:

Antifouling paint, Composite coating, Cu2O, Polymer, UV-thermo-humidity complex stabilityAbstract

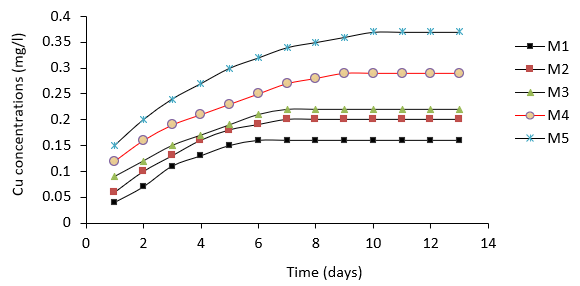

This article introduces results of investigations on Cu2O concentration on release rate of antifouling composite coating for rubber, effects of fineness on ability to release Cu2O of paint (fineness of paint increases, Cu2O release speed of composite coating decreases), effects of period from composite coating preparation to start testing on ability of Cu2O release. Besides, effects of anti-UV additive on ability of composite coating to withstand from UV-thermo-humidity complex was also investigated. Results show that Cu2O concentration is 25 weight percent (wt. %), fineness of paint is 75-80 µm are suitable, period from composite coating preparation to time for being used is about 5 days for the best antifouling grade while ensuring mechanical properties of composite coating. Anti-UV additive of 1 wt. % is suitable for antifouling composite coating for rubber.

Downloads