Design and Fabrication of a Quick Action Medicine Dispensary

DOI:

https://doi.org/10.37934/mjcsm.16.1.4659Keywords:

Automated Medicine Dispensing, Next Generation Medicine, Poly Vinyl Chloride, Polylactic AcidAbstract

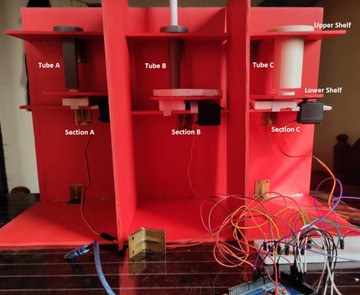

One of the major concerns in the medication process is ensuring that patients take the right medicine at the right time. This issue often necessitates additional assistance, especially for patients who need to take multiple medications multiple times a day, as it can be challenging to remember and manage all medications efficiently. Extensive research has been conducted on developing automated medicine dispensaries to aid patients in this process. However, most existing solutions are either theoretical design concepts or limited to dispensing medicines in batches only. This research aimed to design and fabricate an automated and universal medicine dispensary that addresses the challenges of accessibility and the complexities of scheduled medication intake. This dispensary also provides the capability to dispense medicines both in batches and as single units, according to user requirements. A comprehensive design concept was developed, incorporating essential features such as medicine storage, a user interface, a dispensing mechanism, and a timer system. The prototype was constructed using polyvinyl chloride (PVC) and polylactic acid (PLA), and its functionality was evaluated. The evaluation demonstrated that the automated dispensary could store multiple types of medicines. It featured a compact and user-friendly interface, an accurate alarm system for reminding patients of their scheduled medication times, and a precise dispensing mechanism capable of dispensing medicines discretely and in batches. This automated medicine dispensary, leveraging composite materials like PVC and PLA, has the potential to streamline medication intake processes, enhance healthcare services and revolutionize next-generation medicine.

Downloads