Numerical Investigation of Injection Pressure Effect on the Performance and Emission of a Diesel Engine Fueled with Butanol-Diesel Blends

DOI:

https://doi.org/10.37934/mjcsm.16.1.118Keywords:

Diesel engine, Injection pressure, Split injection, EmissionAbstract

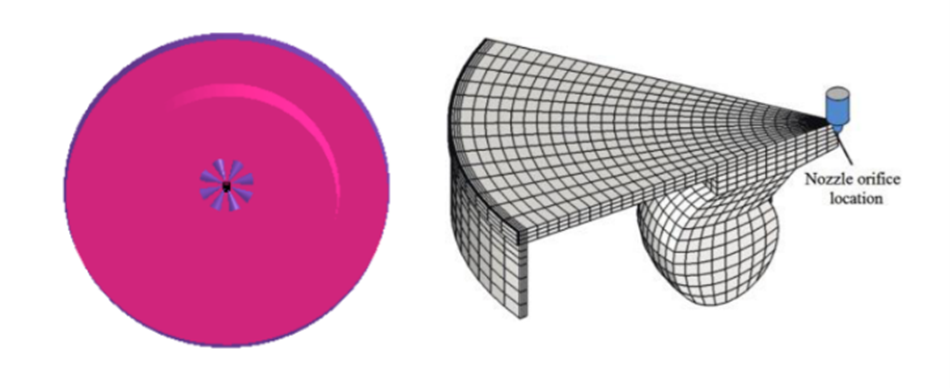

Globally, fossil-based resources are becoming increasingly scarce as the demand for energy from power-producing systems rises. Diesel engines are a popular and efficient source of electricity, but different national and international organizations have imposed limits on diesel emissions. Reducing emissions and boosting performance are typical operations in diesel engines. ANSYS FORTE code was used to generate a thorough numerical configuration. Analyses were conducted on a single-cylinder, four-stroke, direct-injection diesel Cummins N-14 test engine setup running on a 40 percent butanol-diesel blend with injection pressure ranging from 400 bar to 1600 bar at constant speed conditions to determine its performance metrics (i.e. Thermal Efficiency & Specific Fuel Consumption), combustion attributes (i.e. In-cylinder Pressure, In-cylinder Temperature & Apparent Heat Release Rate), and emissions characteristics (i.e. CO emission, Nox emission & Soot emission). In general, as injection pressure was raised, thermal efficiency, CO emissions, and soot emissions all improved, while in-cylinder temperature, in-cylinder pressure & NOx emissions rose progressively. For instance, for 1400 bar fuel injection pressure, maximum in-cylinder pressure and in-cylinder temperature were found, around 18.6 bar and 1650 K, respectively, whereas injection started at a 22-degree crank angle before top dead center (bTDC). The optimal injection pressure for internal combustion engines was determined by considering both emissions and performance. The results indicated that an injection pressure near 800 bar led to the following outcomes: an in-cylinder temperature of approximately 1520 K, an in-cylinder pressure of around 17.5 bar, a thermal efficiency of 32.50%, and a specific fuel consumption of approximately 292 g/KW-h. Additionally, implementing a 90%-10% split injection method with equal crank angle duration (CAD) resulted in an average reduction of 4-6% in NOx emissions.

Downloads