Fill Time Optimization Analysis in Flow Simulation of Injection Molding using Response Surface Method

DOI:

https://doi.org/10.37934/mjcsm.4.1.2839Keywords:

Response Surface Methodology, Plastics Injection Moulding, Fill Time, Optimization, Mold Flow AnalysisAbstract

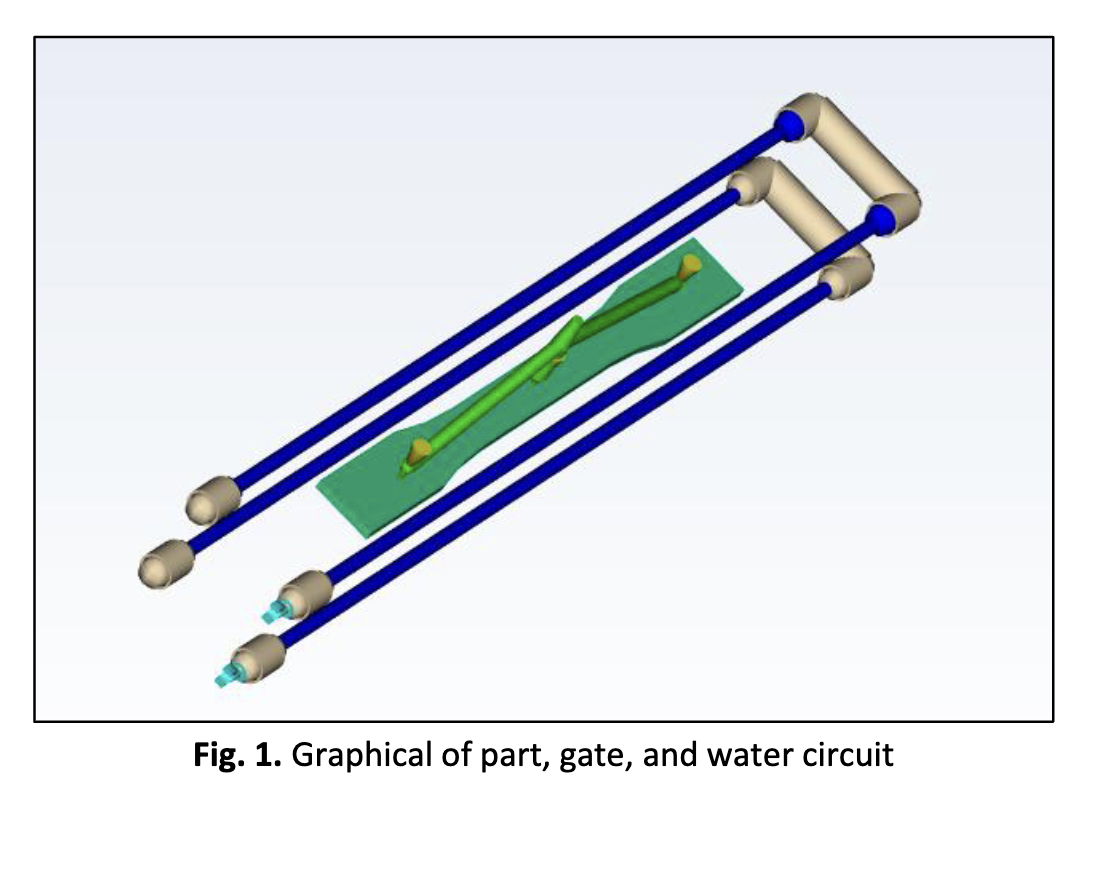

This study focuses on the analysis of fill time by optimizing the injection molding parameters to reduce the defects that are always found on the plastics part such as poor weld line and part not completely filling which can contribute to mechanical properties of the plastic part. The parameters selected for this study are melting temperature, mold temperature, injection time, and the number of gate positions. Response Surface Method (RSM) was used to determine the most significant and optimum parameters on the fill time. From the result analysis, it is found that the injection time is the most significant parameter that affected the fill time with a 99% contribution. The result shows that there is no interaction between process parameters toward fill time which the injection time is the only major factor that affects the fill time. The improvement increases by 0.07% after the optimization process from 4.278s to 4.281s. The most optimum parameters to longer the injection time are mold temperature at 60°C, injection time at 4s, and the number of the gate with two gates position. Thus, the longer the injection time, it can reduce the defect of molded part in the injection molding process.

Downloads