Production of Activated Carbon from Pod Mahogany (Afzelia xylocarpa (Kurz) Craib) Activated by using Potassium Hydroxide

DOI:

https://doi.org/10.37934/armne.20.1.5965Keywords:

Activated carbon, Maca Mong, chemical activation, KOHAbstract

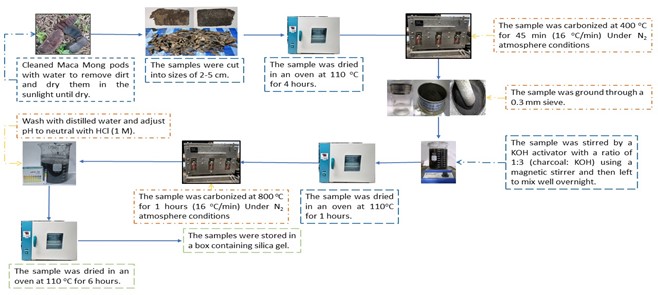

This research aims to study the production of Activated Carbon from Pod mahogany (Afzelia xylocarpa (Kurz) craib) activated by using potassium hydroxide (KOH) for will be used data as a basis for the possibility of further use benefits in the future. The production process of activated carbon from maca pods consists of 2 steps as the carbonization and the chemical activation process at a temperature of 400 oC and held for 45 min (16 oC/min) under N2 atmosphere. When finished, take the Maca Mong pod char and grind it through a sieve size 0.3 mm, then store it in a wrap for use in the second step. The second step, is to take crushed Maca Mong pod Charcoal (0.3 mm) 100 g and 300 g of KOH in a ratio of 1:3 (Charcoal: KOH) mixed into 500 ml of distilled water (water Distilled 5ml/g of Char), then heat it at a temperature of 800 oC for 1 hours (heating rate of 16 oC/min) under N2 atmosphere. The activated carbon (AC) out of the furnace and wash it with distilled water 2 times, slowly adjust the pH value to the neutral value with HCl 1M. When the pH value adjustment is complete, the product was dried in an oven at 110 oC for 6 hrs. Take the AC produced was analysed at the Laboratory. In conclusion, the production of AC from Pod mahogany activated by using KOH in a ratio of 1:3 (Charcoal: KOH) heat it at a temperature of 800 oC for 1 hours (heating rate of 16 oC/min) under N2 atmosphere. The AC can be applied to a variety of applications, such as a gas storage material and as an adsorption material for wastewater treatment or drinking water purification because AC has an adsorption average pore diameter of 17.4486 Angstrom and BET surface area of 1,007.6692 (m2/g).