Effect of Coolant Concentration Ratio on Surface Roughness in Machining Aluminium 6061: A Case Study

DOI:

https://doi.org/10.37934/arefmht.18.1.5568Keywords:

Aluminium, Al6061, coolant concentration, surface roughnessAbstract

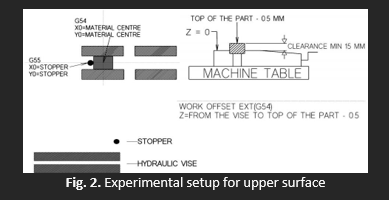

Machining of Aluminium 6061 alloy is critical in various industries, but achieving optimal surface finish while maintaining cost-effectiveness remains a challenge. The concentration of coolants significantly impacts machining characteristics, yet its optimal ratio for specific alloys and processes is not fully understood. This study addresses this gap by investigating the effect of coolant concentration on surface roughness during the machiningof Aluminium 6061 alloy. Two coolants, Coolant A and Coolant B, were evaluated at concentrations of 5%, 7%, 9%, 10% and 11%. The researchemployed a Hision VMC 850 CNC machine with carefully controlled parameters, including a spindle speed of 1500 RPM and specific feed rates. Surface roughness measurements were taken using a Mitutoyo SJ-410 Electronic Surface Roughness tester before and after machining operations.Results demonstrated a clear correlation between increased coolant concentration and improved surface finish for both coolants.Downloads

Download data is not yet available.

Downloads

Published

2025-01-17

How to Cite

Othman Ali, N. H., Admi, A. E., Osman, S. A., & Osman, S. A. . (2025). Effect of Coolant Concentration Ratio on Surface Roughness in Machining Aluminium 6061: A Case Study. Journal of Advanced Research in Experimental Fluid Mechanics and Heat Transfer, 18(1), 55–68. https://doi.org/10.37934/arefmht.18.1.5568

Issue

Section

Articles