Experimental Investigation of Flame Stability and Temperature Profiles in an LPG-Fuelled Combustion System for Industrial Hot Air Generation

Keywords:

Air flow rate, Flame Stability, Hot Air Generation, LPG Combustion, Temperature ProfileAbstract

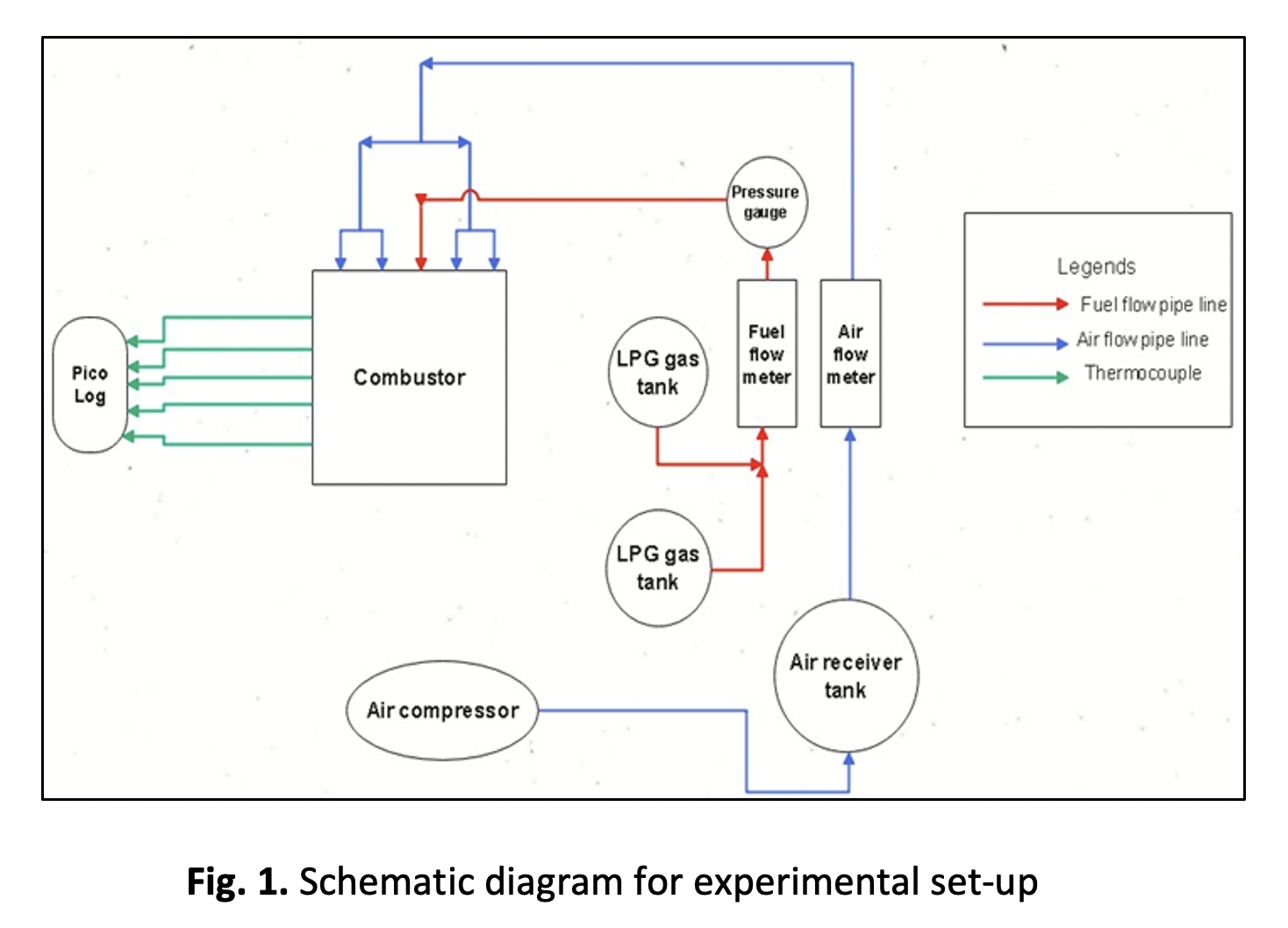

A combustion system is used to produce hot air for a variety of industrial and commercial purposes. This system works by burning a fuel source like natural gas, propane, or diesel in a controlled mixture of fuel and air inside a sealed chamber. However, achieving steady combustion has proven to be difficult since specific air pressure and flow rates are critical. The goal of this experiment was to investigate the combustor's combustion characteristics, particularly flame stability and temperature profile. Low air flow rates required 3 bar of air pressure to ensure flame stability, whereas greater flow rates were able to do so at 2 bar. Air flow rates of 30 l/min and above demonstrated stable flames at a 3 bar pressure. It was found that higher air flow rates were important for flame stability, as a fully opened valve sustained the flame for up to 15 minutes compared to only 4 minutes with a half-opened valve. The temperature profile showed decreased stability at lower air flow rates. Additionally, the maximum temperature of the combustor reached 235 oC, below the auto-ignition range of LPG between 410 oC to 580 oC. Therefore, this study highlights the critical role of air flow rate and pressure in maintaining flame stability and thermal consistency in combustion systems. These findings support efforts to optimize operating parameters of this combustor for improved efficiency, safety, and reliability in industrial applications.Downloads