Minimizing Total Production Cost in Hybrid Flow Shop Scheduling using Taguchi Enhanced Particle Swarm Optimization Algorithm

DOI:

https://doi.org/10.37934/ard.132.1.4151Keywords:

Cost optimization, PSO tuning, hybrid flow shop, metaheuristics, Taguchi designAbstract

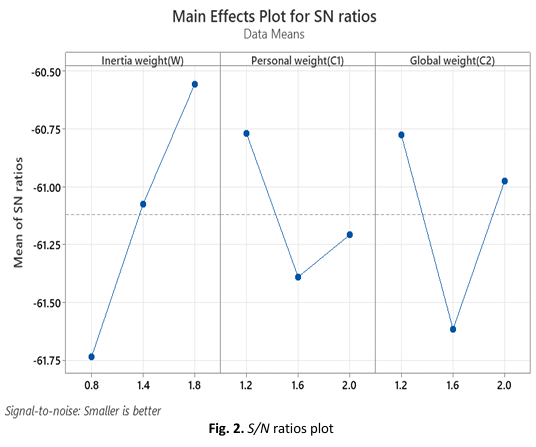

This study uses metaheuristic optimization algorithms to minimize the total production cost (TPC) in a hybrid flow shop scheduling (HFS) environment. Scheduling jobs in manufacturing systems is vital for fulfilling customer demands and improving efficiency. In this research, four well-established metaheuristic algorithms, namely Tuned Particle Swarm Optimization (TPSO), Standard particle swarm optimization (PSO), Sine cosine algorithm (SCA) and Arithmetic optimization algorithm (AOA), were explored for TPC optimization in HFS using MATLAB (2022b). Through experimental analysis, TPSO consistently provided the best solutions regarding mean fitness, outperforming other algorithms in a maximum of 12 benchmark test problems. Taguchi's Design of Experiment (DOE) was utilized to identify the most influential parameter configurations for PSO. The findings highlight the effectiveness of TPSO in minimizing production costs and improving productivity in HFS. This research contributes to production scheduling and offers insights for organizations striving to optimize manufacturing systems utilizing the HFS environment.

Downloads