Recent Progress in Proppant Technology for Improving the Fracture Conductivity in Hydraulic Fracturing

DOI:

https://doi.org/10.37934/ard.127.1.96119Keywords:

Hydraulic fracturing , proppant, resin coated proppant, unconventional reservoir, nanofiller, nanomaterialAbstract

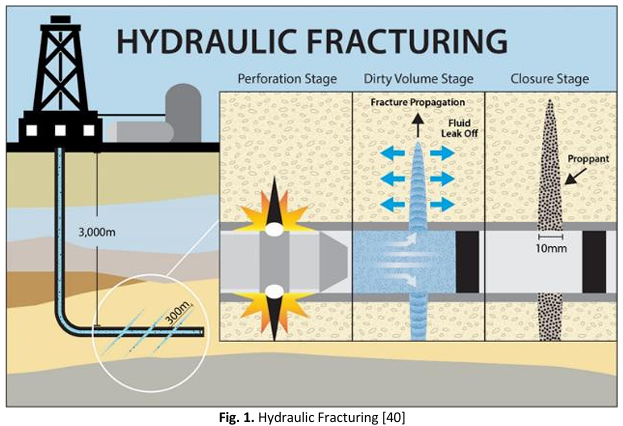

Proppants play a crucial role in hydraulic fracturing (HF) operations and in sustaining conductive fractures during well production. However, challenges persist regarding their resilience to closure stress and downhole conditions. Coatings have emerged as a promising solution to enhance proppant efficacy, particularly in addressing mechanical failure. This study highlights the recent advancement in proppant technology and focuses specifically on the impact of different resins coated proppants in improving the fracture conductivity after HF operation. Polymer coatings, especially thermosetting-based resin coatings are widely used due to their ability to improve both the strength and flexibility of the coated proppants. Proppants coated with a thin layer of resin offer several advantages, including good permeability, shape improvement and lower cost compared to regular coatings. Additionally, the incorporation of nanomaterials into resin coatings has shown promising results in augmenting proppant durability and flow conductivity as well as enhancing embedment prevention, reducing the generated fines after proppant crushing and improving the overall oil and gas production rate. For that, a summary was presented of the latest academic discussions and conclusions on the impact of resin coating on proppant and its pivotal role in enhancing proppant performance which led to increased fracture conductivity. Leveraging insights garnered from these discussions can positively contribute to the sustainable extraction of hydrocarbon resources in the oil and gas industry.

Downloads