Bending Stress Analysis of Natural Fibre Reinforced Composite Gears

Keywords:

Spur gear , natural fibre composite , finite element analysis (FEA) , AGMAAbstract

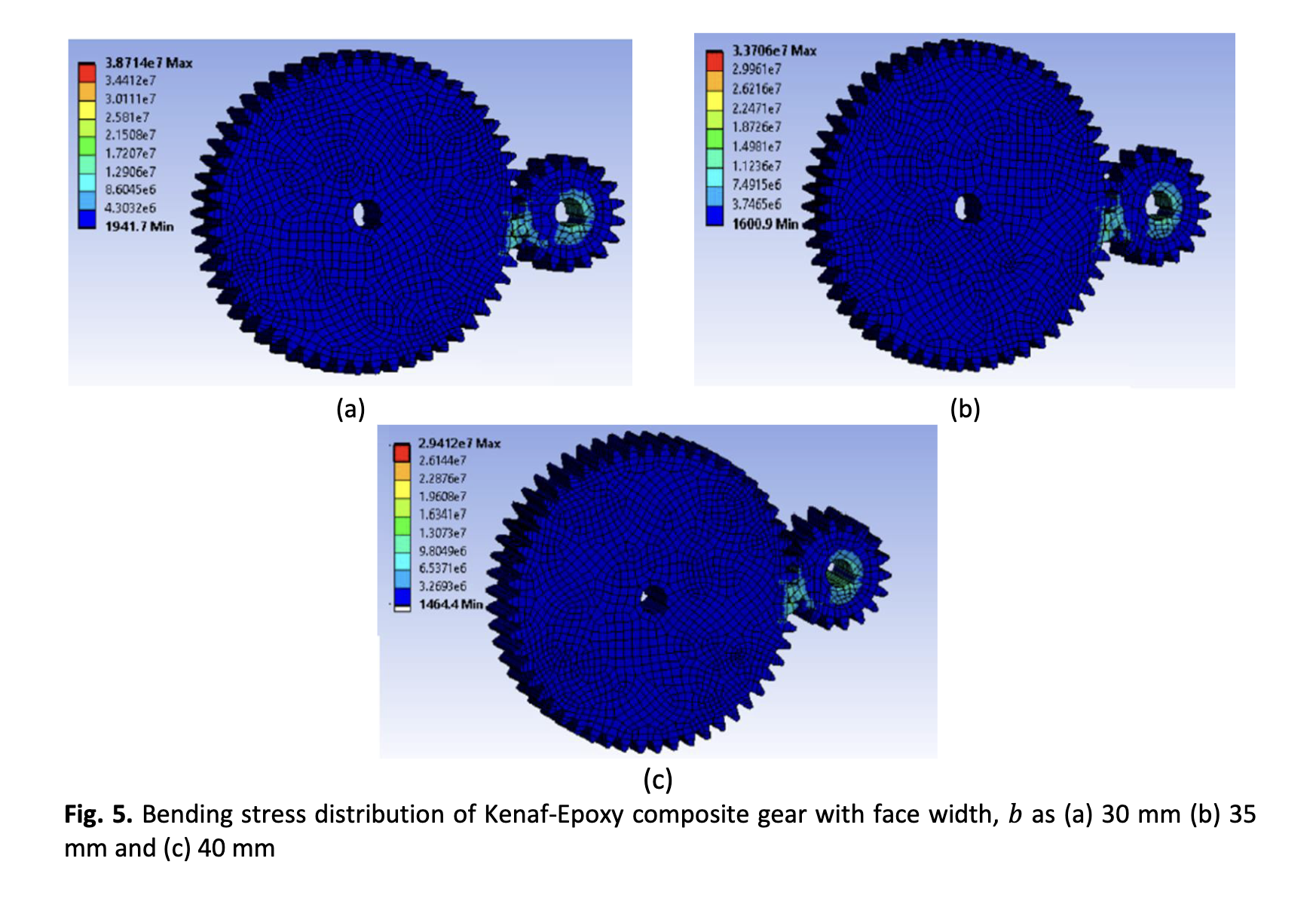

Spur gear is an essential element in mechanical power transmission systems. While the gears have been made of metals in most application, the gears in recent years have been made of composite materials to take advantage of the specific strength and low weight of the composites. Due to harsh loading condition at contact line of the gear, it is subjected to failure due to bending and contact stress. In this study, bending stress analysis was conducted on composite spur gears using finite element method (FEM). SolidWorks software was used to design the 3D models of gears before the models were exported to the FEM software of ANSYS. Within ANSYS Workbench, bending stress analysis was firstly conducted on ANSI 1040 steel gear where the results were then validated with the stress values obtained using the American Gear Manufacturing Association (AGMA) formulation and past results. The validation study showed an excellent agreement between the three values of the finite element analysis (FEA) result, the AGMA formulation and the past result. Following this, stress analysis was conducted on composite gear with Epoxy resin while applying 3 kinds of fibre namely Kenaf, Pineaple leaf fibre (PALF) and E-Glass. The effect of the face width of the gear on the bending stress was studied by varying the face width values to 30, 35 and 40 mm. The results indicated that each three fibre type gave similar values of maximum bending stress. However, the ultimate tensile strength failure will first go to Kenaf, followed by PALF and E-Glass fibre. Furthermore, the values of stress can be seen to decrease with the increase of face width.

Downloads