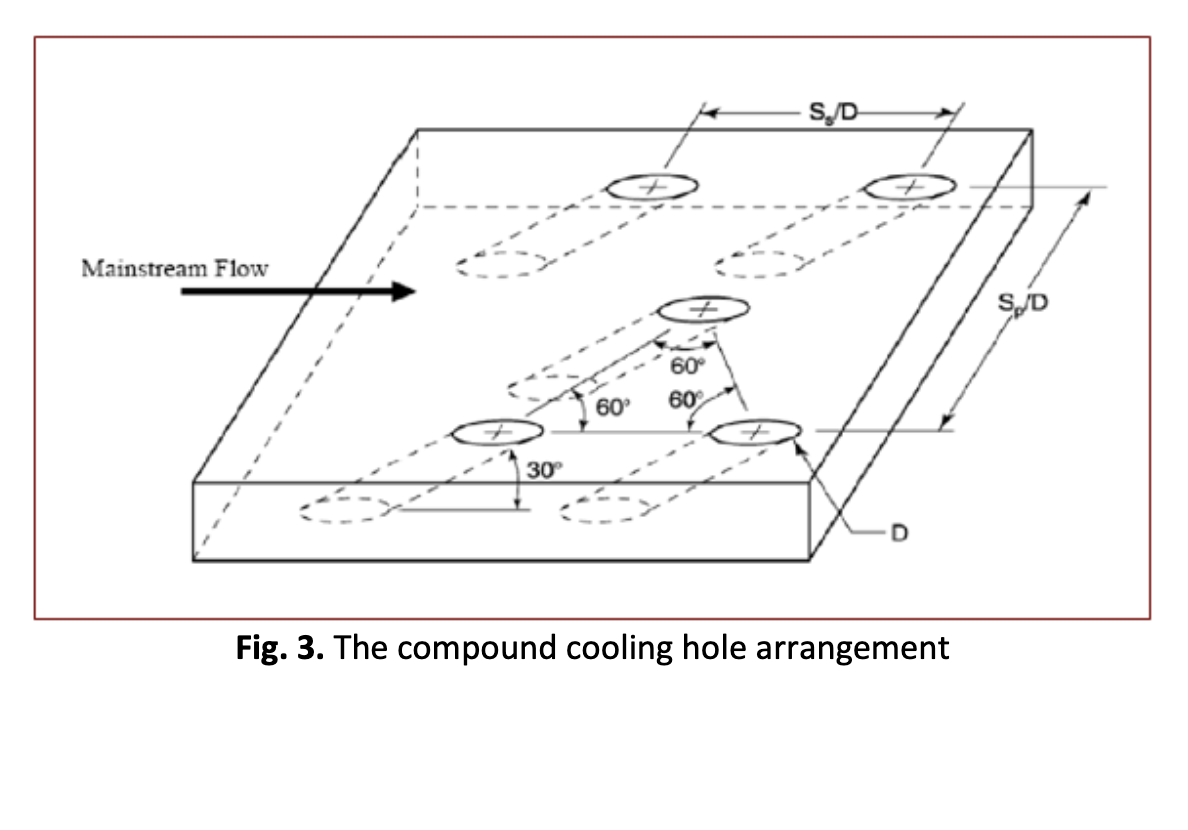

Analysis of External Film Cooling Effectiveness using Compound Cooling Holes

Keywords:

Gas turbine, turbine technology, material propertiesAbstract

By using the well-known Brayton cycle, great turbine industries are always in a revolution phase to further improve the nowadays technology. One of the ways to improve turbine performance is by increasing the turbine inlet temperature. However, the turbine inlet temperature increment creates a harsh environment for the components of the combustor. This is due to the high temperature of air exceeding the melting point of material inside the combustor. So the proper cooling technique needs to be implemented. Compound cooling holes are a useful way to this achievement. This study was accomplished to investigate the effects of cylindrical and row compound cooling holes with alignment angles of 30 degrees and beta of 0,10,20,30 and 40 degrees. This model was simulated and analyzed with a commercial finite volume package ANSYS FLUENT 14.0. Analysis of the findings of the study showed that using the row compound cooling holes of 30 degrees provides better cooling performance than other degrees. The film cooling effectiveness is also higher when blowing ratio is 1.5 compared to 1.

Downloads