Effect of Fibre Direction on Repairing Tensile Failure of Glass Fibre/Polyester Composite

Keywords:

fibreglass, repaired fibreglass, fibre direction, tensile test, burnout testAbstract

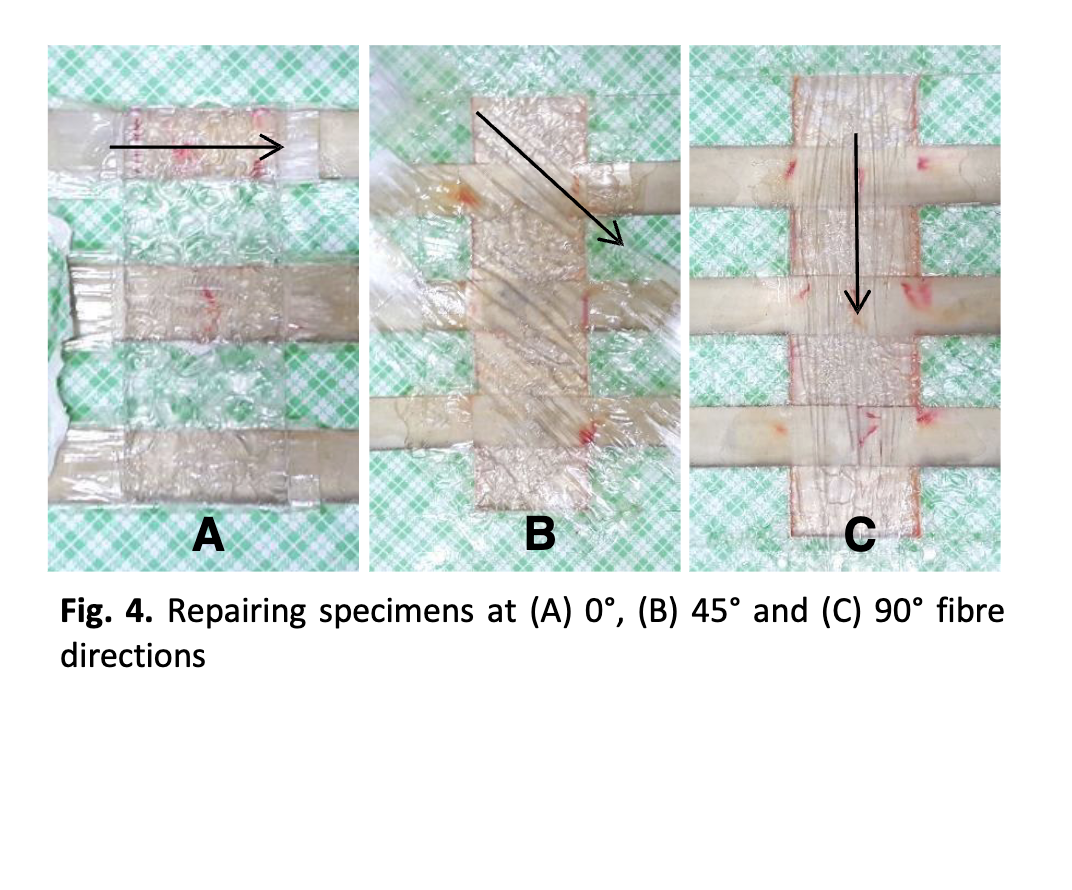

Orientations of the fibres play important roles to improve the strength and stiffness of a composite. This study is focused on the effect of fibre directions of a composite at 0º, 90º and 45º on repairing tensile failure of glass fibre/polyester composite. This experiment, carried out to investigate said effects using on fabricated unidirectional glass fibre that drawn from a woven glass fibre with polyester resin used as the binding materials. Unidirectional test specimens had been successfully fabricated, fractured and then repaired with varying fibre directions. Tensile tests on the repaired composite specimen were prepared according to the ASTM D3039/D3039M. The repairs with 0º, 45º and 90º fibre direction provided the highest tensile strength at 119.234 MPa, 53.270 MPa and 31.943 MPa respectively. The average Young Modulus results on all three series of specimens mended with 0º, 90º and 45º fibre directions are at 10217.505 MPa, 7239.747 MPa and 12103.192 MPa respectively. Physical compositions for the fabricated specimens were determined with burnout test. The fibre weight and volume ratio of 0º and 90º fibre directions show some consistency at 0.47 and 0.344 respectively. The fibre weight and volume of the 45º fibre direction is the highest at 0.506 and 0.354 due to its fibre repair directions.

Downloads