Heat Transfer Performance of Hybrid Nanofluid as Nanocoolant in Automobile Radiator System

Keywords:

Graphene, erosion-corrosion, water pump, coolant, tribological impactAbstract

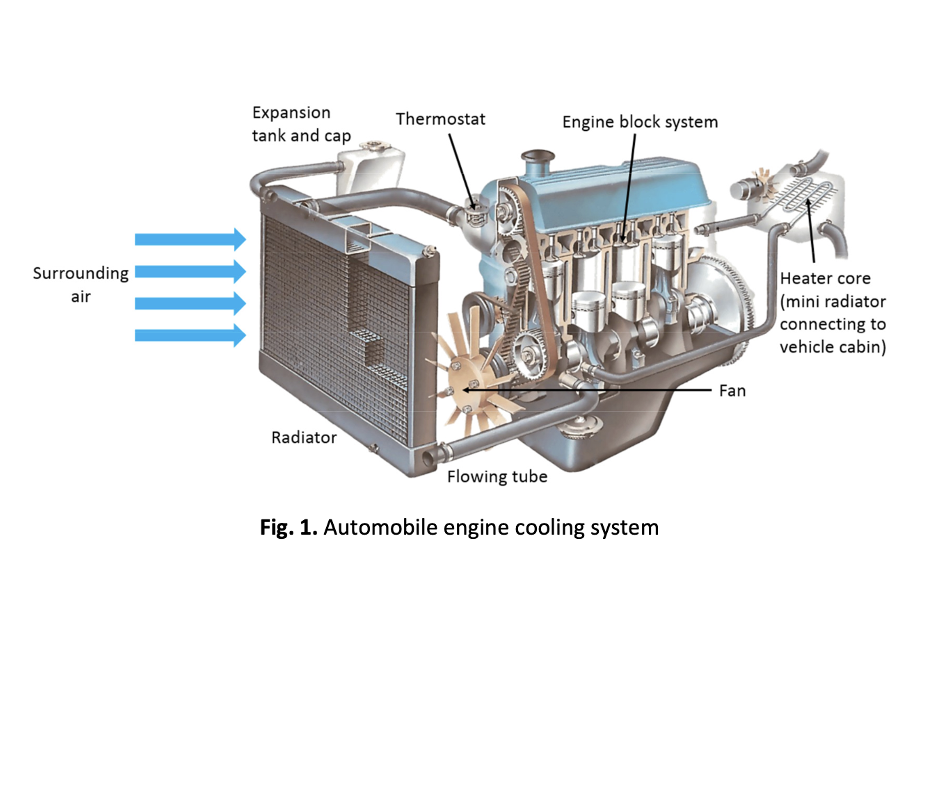

In automobile cooling system, mixture of water and ethylene glycol is widely used as coolant. For many years, nanofluid has been reported to enhance thermal properties of conventional heat transfer fluid due to dispersion of solid particles which exhibit superior thermal conductivity. Many past researchers found significant improvement of heat transfer rate in automobile cooling system by adopting nanofluid as coolant. However, most of them reported on drawback of using nanofluid such as low stability, high cost and high pressure drop but not trobological impact. Thus, this research tends to determine stability, thermophysical properties, hydrothermal performance and erosion-corrosion effect of a novel hybrid nanofluid in automobile cooling system. Stability test of proposed nanofluid will be evaluated based on zeta potential and absorbance value. After that, thermophysical properties measurement

of nanofluid will be carried out using the most stable preparation method. Hydrothermal performance of the novel nanofluid will be evaluated using Goodness

factor. For erosion-corrosion study, working parameters and procedures followed ASTM D2809-09 standard. Each pump surface profile was inspected using 3D imaging microscope to obtain surface change details. In addition, precise weight measurement was carried out to determine total material loss due to various

coolants. It was observed that corrosion effect was about the same for base coolant and nanocoolants. Material loss due to erosion-corrosion effect was increased with increasing concentration of graphene nanoplatelets in coolant. Based on ASTM 2809- 09 standard, erosion-corrosion damage on impeller using these nanocoolants was found to be minimal and can be considered to be incorporated in future cooling system.

Downloads