Design and Development of a Coconut DeHusking Machine (Machine Component Design)

Keywords:

Mechanical mechanism, machine efficiency, machine capacitiesAbstract

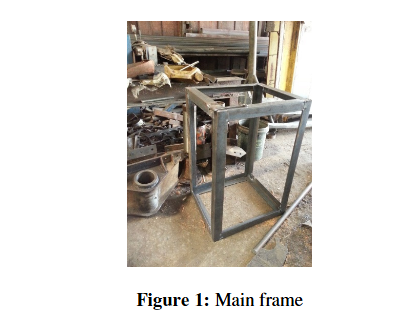

A coconut de-husking machine comprising of two rollers with spikes, chain drives, presser, clearers, shafts and belting system was developed for small-scale production in rural areas. Performance test analysis showed that the machine de-husks coconut fruits without any nut breakage or distortion of the extracted fibre length. The objective of this project is to improve the efficiency and productivity in producing coconut fruits without husks by using the best selection of mechanical mechanisms with minimum costs. One electric motor (2hp, 1500rpm) is used to drive two shafts using a combination of pulley and belt. In between the motor and the shafts, one box of worm gears is used to reduce the rotation speed from 1500rpm to 21rpm (ratio 70:1). Two metal cylinders with a series of spikes are used to remove the husks from the coconut fruit and are attached to the rotary shaft. The machine’s average de-husking efficiency and capacity are 90.42% and 222 coconuts per hour, respectively. In addition, the development of the machine is also a solution to the constraint of space,

whereby a compact-size machine is more suitable for small and medium enterprises (SME’s). Plus, it operates with lesser noise, which also contributes to a more viable operating condition for the environment.

Downloads