Peeling Strength of Facesheet Thickness on Rubber Wood Honeycomb Composites

Keywords:

Rubber wood, Honeycomb core, Facesheet thickness, Vertical 90°, PeelAbstract

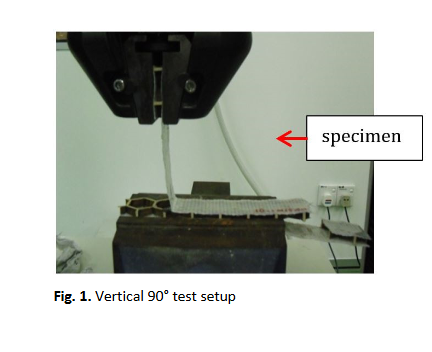

Honeycomb with good mechanical properties and low density are the top priorities in material selection. Therefore, the facesheet thickness is a factor that contributes to it as it made up most of the weight in the structure. Appropriate thickness can optimize the mechanical performance. However, the sandwich composite may associate to high density if the facesheet is of high thickness yet deteriorate the mechanical properties as an overall. As the facesheet is attached to the sandwich structure via matrix, the peeling properties for various facesheet thickness is investigated. The facesheet thickness in terms of one to five layers are glued to the rubber wood core. The structures are tested for its peeling strength under vertical 90° test according to the ASTM standard. The optimal number of facesheet with good peeling strength is discussed.

Downloads