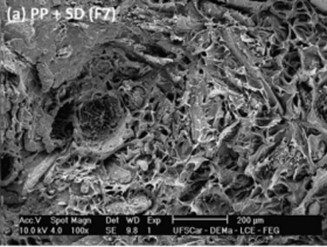

Fracture Mechanism of The Nanocomposite and Optimized Injection Moulding Processing Condition

DOI:

https://doi.org/10.37934/armne.20.1.7995Keywords:

Fracture mechanism, polymer nanocomposite, natural fibre, injection moulding optimization, pavement applicationAbstract

The importance of innovative technology aimed at conserving natural resources and protecting the environment in the construction sector cannot be overstated. The current trend in recent research efforts at the academic and industrial levels taking place all over the world is the development of novel substitute materials to existing conventional metals, alloys, concrete, and synthetic materials. Industries are focusing more on minimizing atmospheric pollution to earn carbon credits. Utilizing natural resources to create composite materials that are totally or partially biodegradable is a tiny step toward protecting the environment. Engineering and environmental considerations are involved in the usage of natural fibre in polymer natural fibre nanocomposites for pavement application. The problem with using concrete or cement is each ton of cement produced to make a pavement block emits one ton of carbon dioxide CO2, which has a negative impact on the environment. The development of multifunctional materials and structures for cutting-edge applications has new paths thanks to the usage of these fibres/fillers as reinforcement in a variety of polymeric materials. This article intends to cover the implication of polymer natural fibre nanocomposites to pavement applications and review the fracture mechanism of the nanocomposite and optimized injection moulding processing condition.