Effect Of Ultrasonically Vibrated Cutting Tool on Surface Roughness of Micro Turning

DOI:

https://doi.org/10.37934/armne.20.1.3543Keywords:

Micro turning, ultrasonic vibration assisted turning, ploughing, surface roughnessAbstract

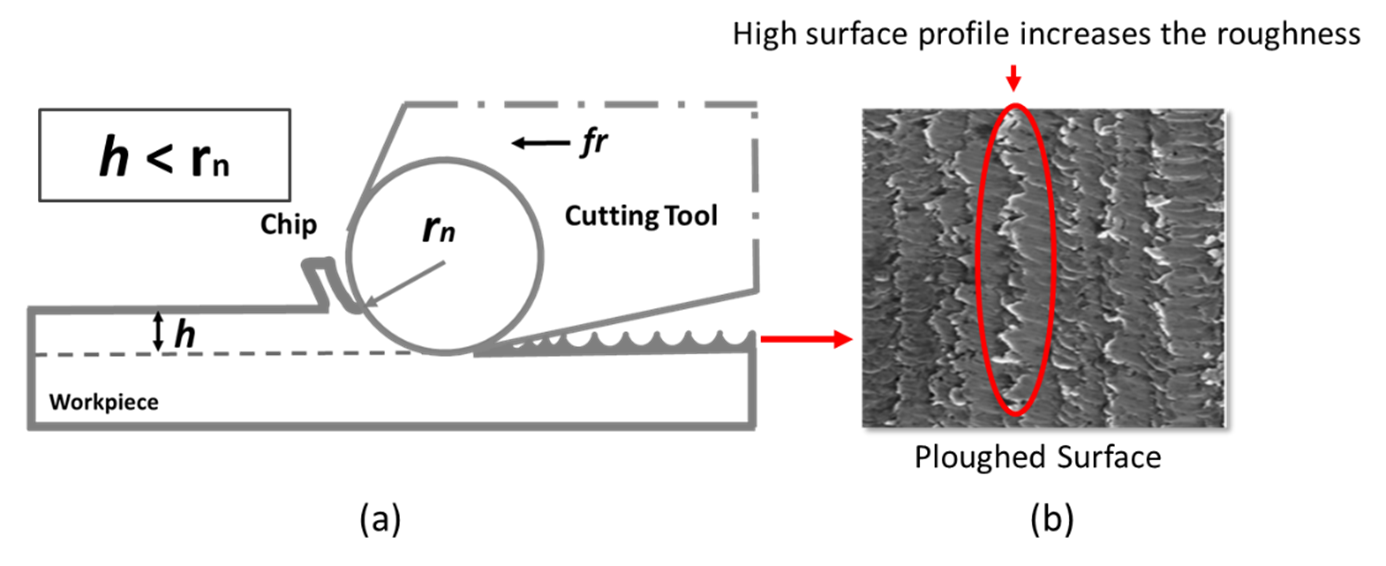

Micro turning is commonly employed in the manufacturing of precision parts. However, the precision may get compromised by the chronic phenomenon of micromachining called ploughing. Ploughing produces extra roughness, as some cut surfaces are ploughed by the cutting tool. It is expected that any disruption to these continuous interactions could mitigate this unwanted condition. Therefore, Ultrasonic Assisted Vibration Turning (UVAT) was proposed, utilizing its intermittent cutting to reduce the contact between the cutting tool and the workpiece. In this study, the impact of Longitudinal (LVAT) and Tangential (TVAT) UVAT on surface roughness in micro turning of aluminium alloy was investigated. The experimental data suggests that LVAT and TVAT affect differently on reducing the surface roughness of the micro-turned Al-6061. However, LVAT proves to be more effective in suppressing the negative effects of ploughing at high feed rate cuttings, as indicated by a smoother machined surface. LVAT reduced surface roughness by 12% greater than TVAT at a cutting feed rate of 0.48 mm/rev. These findings support the potential of UVAT, particularly the LVAT technique, as a viable approach to enhance surface quality in micro turning applications for precision engineering.