Valorization of Active Agent Nanochitosan-Catechin in Development Mechanical Properties Based on Polylactid Acid (PLA)- Polycaprolactone (PCL) Mixture

DOI:

https://doi.org/10.37934/armne.20.1.1016Keywords:

Bioplastic, PLA, polymers, nanochitosan, mechanical propertiesAbstract

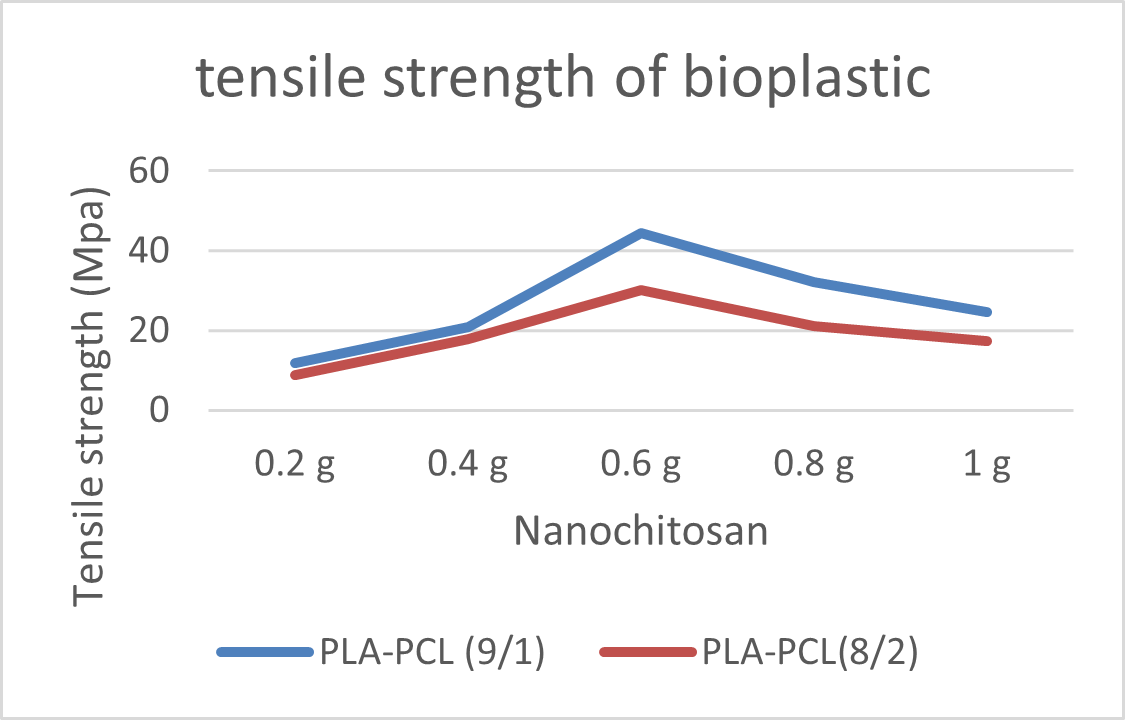

The circular economy was created to convert waste resources into economic products by implementing various strategies, two of which are: using materials from renewable sources and producing biodegradable products. The aim of this research is to manufacture polylactid acid (PLA) which is usually made from fermented plant starch, and a mixture of polycaprolactone (PCL), a biodegradable polyester, to investigate its potential use as a substitute for oil-based commodity plastics. The PLA/PCL mixes were mixed in batches using a lab-scale internal mixer and then printed. The mechanical strength of the resulting bioplastic was tested using the UTM d638 tool. It has been found that incorporating PCL into the PLA matrix can produce materials with tensile strengths ranging from 8.67 to 44.48 mPa. The incorporation of PCL significantly increases the toughness of PLA, increasing the energy required to fracture the specimen. Based on the results of GC-MS compounds like Beta elemene, Caryophyllene, Methanodrostonole, Alpha humulene, and Gamma gurjenene from jamblang seeds have good antioxidant activity. The addition of active compounds in the matrix must be considered in the study of the durability and stability of the PLA-PCL packaging film. When the active ingredient was added more than 7%, the tensile strength decreased drastically due to the only interaction between the active agent in the form of catechin and chitosan. Overall, the obtained PLA/PCL blends were found to be a strong and environmentally friendly alternative to oil-based commodity materials.