Process Control in Torrefaction: Design and Experimental Investigation of a Custom Oven using Fuzzy Logic Algorithms

DOI:

https://doi.org/10.37934/arefmht.21.1.8495Keywords:

Custom-made oven, Experimental study, Fuzzy logic control, Torrefaction processAbstract

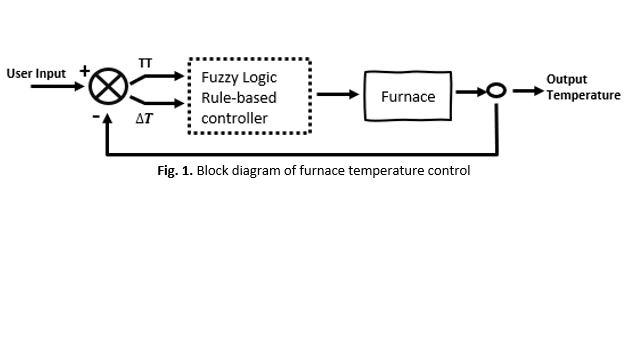

In heating systems, overshoot refers to the phenomenon where the temperature exceeds the intended setpoint prior to stability, resulting in inefficiencies, potential deviations from expectations, and safety hazards. This project introduces a custom-made designed oven (CMDO) utilising Fuzzy Logic Control (FLC). It analyses the behaviour of the CMDO and implements 36 FLC-based rules to minimise overshoot, optimising factors such as rise time and settling time. Experimental studies on the oven are being conducted to analyse its behaviour with varying PWM (Pulse Width Modulation) across a temperature range of 100 to 500 degrees.The oven's performance was evaluated by collecting data using a K-type thermocouple sensor, with temperature readings recorded in a CSV file. The collected data were analysed to assess oven performance, followed by fine-tuning if the performance was deemed unsatisfactory. The implementation of FLC has resulted in an average improvement of overshoot by up to 90% across temperatures ranging from 100 to 400 degrees, with a significant enhancement in settling time at temperatures below 200 degrees. However, temperatures above 300 degrees have exhibited a slight increase in settling compared to conditions without FLC. The results indicate that torrefaction is a more effective pre-treatment method for municipal solid waste (MSW) than the conventional thermal drying process. The torrefaction results were compared with previous research, revealing similar trends and thereby validating the operation and yield of the developed system.

Downloads