Vortex Control at Pump Intake using Double- and Triple-Plate Floor Splitters

DOI:

https://doi.org/10.37934/arefmht.21.1.193200Keywords:

Anti-vortex device (AVD), swirl angle, particle image velocimetry (PIV), double-plate floor splitter (DPFS)Abstract

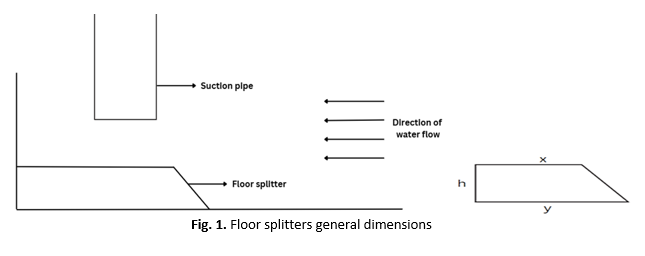

Vortices are one of the main contributors to efficiency loss and damage issues in centrifugal pump components, particularly those aligned with the axis that facilitates water transfer from the reservoir. This problematic scenario arises due to a non-optimal pump reservoir design and irregular water flow entering the reservoir. The unsteady flow disrupts the pump's functionality, leading to inefficiency and potential damage over time. However, this issue can be mitigated by installing anti-vortex devices (AVD) around the pump reservoir. The ANSI/HI 9.8 2018 standard outlines various AVD designs, specifying that the swirl angle in the flow should not exceed 5° to ensure efficient operation. Here, we use customised double- and triple-plate floor splitters (DPFS and TPFS). A floor-type flow separator plate is an effective measure to reduce swirls and vortices in the pump intake flow. Vortex intensity was measured using a swirl meter, and it was found that installing a plate in a single-pump system could reduce swirl angle by approximately 60%. The approach used involved visualizing flow structures with a particle image velocimetry (PIV) device to obtain data on vortex intensity before and after the plate installation. In an effort to improve AVD design, six plate samples with different dimensions were tested. This study also examined the effects of adding plates to the AVD design to optimise flow separator design in various pump reservoir geometries. We found that the DPFS 260 mm (25 mm) setup effectively minimised vortex formation with a high reduction in vorticity. The results of this experiment can provide guidance for reducing vortex problems in pump reservoirs, which in turn can save time and cost in pump system planning and management.

Downloads