Study on Flow Velocity Effect to Corrosion Rate of Mild Steel

DOI:

https://doi.org/10.37934/arefmht.21.1.7783Keywords:

Capillary pipes, refrigeration system, COPAbstract

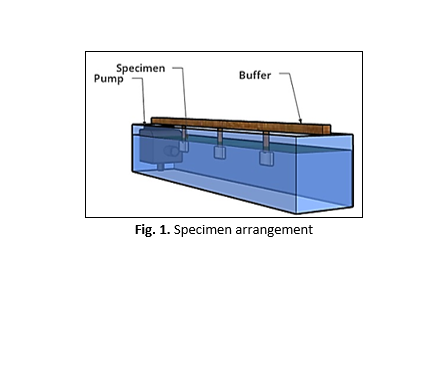

The use of iron and steel as the main material for shipbuilding is still dominant. However, iron and steel are highly reactive and corrode in seawater and it has become the biggest causes of ship plate damages. In this study, the calculation of relatively fast corrosion propagation on low-carbon steel plates by comparing the corrosion rate on moving samples will be investigated. In this study, researchers examined the comparative effect of flow speed, time, pH, and salinity on specimens. Researchers used a method that looks at the initial mass of a sample before it is placed in a corrosive environment over a period of time, then reweighs the sample to measure the weight lost due to corrosion. Changes in flow velocity affect the corrosion rate of each specimen. The highest corrosion rate was found in specimens immersed with a flow speed of 0.3 m/s at 4.741 mm/year, and the lowest was found in specimens immersed with a flow velocity of 0.1 m/s at 0.244 mm/year. The faster the flow of water, the greater the corrosion rate. The variation of the corrosive media also affects the corrosion rate. The corrosion rate can increase as the pH decreases and the level of salt or salinity in the corrosive media increases. The highest corrosion rate value is found in specimens immersed in media with a pH of 5 and a salinity of 3.7% at 4.741 mm/year, and the lowest is found in specimens immersed in media with a pH of 9 and a salinity of 3.3% at 0.244 mm/year.

Downloads