Experimental Evaluation of the Performance of a Diesel Engine Feeding with Ethanol/Diesel and Methanol/Diesel

DOI:

https://doi.org/10.37934/arefmht.15.1.1427Keywords:

Diesel engine, engine performance, Ethanol-Diesel blend, Methanol-Diesel blendAbstract

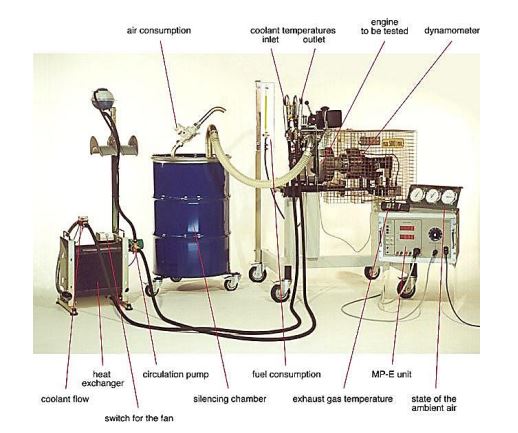

Nowadays, decreasing sources of petroleum fuel has led to innovation of other resources. Alternative fuel can be produced from biomass such as alcohol. In this work, an experimental study on the feasibility and the effects of using Diesel-ethanol and Diesel-methanol blends as alternative fuel for Diesel engine was carried out. Pure Diesel, Diesel-ethanol, D95E5, D90E10 and D85E15 as well as Diesel-methanol, D95M5, D90M10 and D85M15 on Farymann four stroke monocylinder Diesel engine performances was completed. The engine is tested at full load with engine speed ranged from 700 to 3000 tr/min. The effects of ethanol and methanol fraction on diesel engine power, torque, brake specific fuel consumption (BSFC), brake thermal efficiency and exhaust temperature were experimentally investigated. The results showed that mixing ethanol and methanol at different fractions with Diesel fuel have a significant effect on the engine performance, as well as the nature of alcohol, which constitutes a combustion catalyst. Fuel mixtures, D85E15 and D85M15 have the highest improvement rates compared to pure Diesel and other examined fuel mixtures. It has been shown, that, the lowest BSFC than that of pure Diesel, which is an advantage for our proposed fuels, is recorded with D95E5 and D95M5 blends. The different mixtures provide higher exhaust gas and outlet temperature of the coolant proportional to the mixing ratio, which explains why the addition of biofuel improves the calorific value of the fuel. The combustion of the different mixtures increases the outlet temperature of the coolant in proportion to the mixing rates.

Downloads