Enhancing Biogas Yield through Anaerobic Co-Digestion of Animal Manure and Seaweed

DOI:

https://doi.org/10.37934/progee.28.1.122Keywords:

Animal manures, Seaweed, Co-digestion, Biogas yield, Mesophilic temperatureAbstract

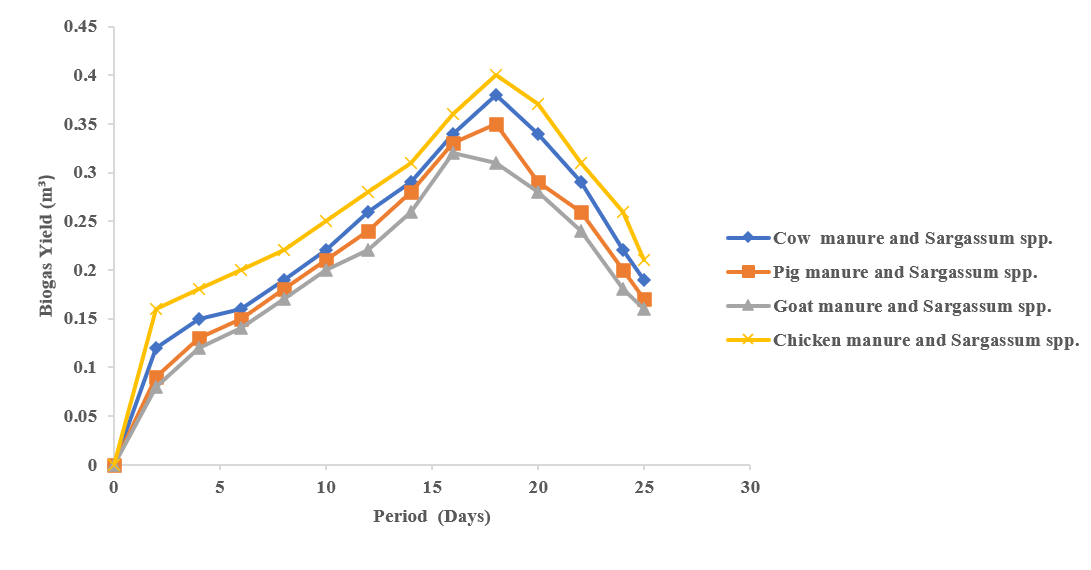

By 2050, it is predicted that there will be 9.8 billion people on the planet. The world's population is expanding, which creates an immediate energy demand, the majority of which is now provided by fossil fuels. Researchers are becoming more interested in seaweeds because they offer a sustainable and viable feedstock for the manufacture of biofuels. They are a good alternative energy source to fossil fuels because of their readily fermentable composition, high availability, and good degradation potential. The current work focuses on the co-digestion of animal manures with Sargassum spp., namely goat, pig, cow, and chicken manures. The study was conducted under mesophilic temperature conditions, i.e., +/- 37°C at a hydraulic retention time (HRT) of 25 days. The findings were presented in terms of daily, cumulative, and total biogas production. From the biogas yield results obtained, it is apparent that the co-digestion of goat, pig, cow, and chicken manures with Sargassum spp. produced an improved biogas yield, unlike the substrates of sole digestion. Besides, the maximum total cumulative biogas yield of 3.51 m3 was obtained with co-digestion of chicken manure and Sargassum spp., while the least total cumulative biogas yield of 2.68 m3 was achieved with co-digestion of goat manure and Sargassum spp. Also, an optimum biogas yield was achieved with a mesophilic temperature of 37°C and the lowest biogas yield with a mesophilic temperature of 31°C.

References

A.T. Hoang, J.L. Goldfarb, A.M. Foley, E. Lichtfouse, M. Kumar, L. Xiao, S. F. Ahmed, Z. Said, R. Luque, V. G. Bui, Production of biochar from crop residues and its application for AD, Bioresource Technology 363 (2022)127970. https://doi.org/10.1016/j.biortech.2022.127970.

E.K. Orhorhoro, P.B. Ebunilo, E.G. Sadjere, Effect of Organic Loading Rate (OLR) on biogas yield using a single and three-stages continuous anaerobic digestion reactors, International Journal of Engineering Research in Africa 39 (2017)147-155. https://doi.org/10.4028/www.scientific.net/JERA.39.147.

R. Franqueto, J.D., da Silva, and M. Konig, Effect of temperature variation on co-digestion of animal waste and agricultural residue for biogas production. BioEnergy Research 13 (2) (2020) 630–42. https://doi.org/10.1007/s12155-019-10049-y.

S. Bi, X. Hong, H. Yang, X. Yu, S. Fang, Y. Bai, and Y. Wang, Effect of hydraulic retention time on anaerobic co- digestion of cattle manure and food waste, Renewable Energy 150 (2020) 213–20. https://doi.org/10.1016/j.renene.2019.12.091.

R. Karki, W. Chuenchart, K.C. Surendra, S. Shrestha, L. Raskin, S. Sung, and S.K. Khanal, Anaerobic co- digestion: Current status and perspectives, Bioresource Technology 330 (2021)125001. https://doi.org/10.1016/j.biortech.2021.125001.

J. Zhang, C. Qi, Y. Wang, Y. Li, T. Han, X. Gong, M. Shan, G. Li, W. Luo, Enhancing biogas production from livestock manure in solid-state anaerobic digestion by sorghum-vinegar residues, Environmental Technology & Innovation 26 (2022) 102276. https://doi.org/10.1016/j.eti.2022.102276.

W.L. Chow, S. Chong, J.W. Lim, Y.J. Chan, M.F. Chong, T.J. Tiong, J.K. Chin, G.T. Pan, Anaerobic co-digestion of wastewater sludge: A review of potential co-substrates and operating factors for improved methane yield, Processes 8 (2020) 39. https://doi.org/10.3390/pr8010039.

A. El Nemr, M.A. Hassaan, M.R. Elkatory, S. Ragab, A. Pantaleo, Efficiency of Fe3O4 Nanoparticles with Different Pretreatments for Enhancing Biogas Yield of Macroalgae Ulva intestinalis Linnaeus, Molecules 26 (2021) 5105. https://doi.org/10.3390/molecules26165105.

D. Singh, K. Malik, M. Sindhu, N. Kumari, V. Rani, S. Mehta, K. Malik, P. Ranga, K. Sharma, N. Dhull, Biostimulation of anaerobic digestion using iron oxide nanoparticles (IONPs) for increasing biogas production from cattle manure, Nanomaterials 12 (2022) 497. https://doi.org/10.3390/nano12030497.

E.K. Orhorhoro, O.W. Orhorhoro, P.O. Ebunilo, Analysis of the effect of Carbon/Nitrogen (C/N) ratio on the performance of biogas yields for non-uniform multiple feed stock availability and composition in Nigeria, International Journal of Innovative Science, Engineering & Technology 3(5) (2016) 119-126

R. Chandra, H. Takeuchi, Methane production from lignocellulosic agricultural crop wastes: A review in context to second generation of biofuel production, Renewable and Sustainable Energy Reviews 16(3) (2012) 1462-1476. https://doi.org/10.1016/j.rser.2011.11.035.

H. Abu-Qdais, K. Bani-Hani, N. Shatnawi, Modeling and optimization of biogas production from a waste digester using artificial neural network and genetic algorithm, Resources, Conservation and Recycling 54 (2012) 359–363. https://doi.org/10.1016/j.resconrec.2009.08.012.

M.I. Tanimu, T.I.M. Ghazi, R.M. Harun, I. Adris, Effect of carbon to nitrogen ratio of food waste on biogas methane production in a batch mesophilic anaerobic digester, FOG. 24(18) (2014) 34-49.

A. Tardast, M. Rahimnejad, G. Najafpour, Prediction of bioelectricity production by Neural Network, Journal of Biotechnology and Pharmaceutical Research 3(3) (2012) 62–68

F. Wang, M. Pei, L. Qiu, Y. Yao, C. Zhang, H. Qiang, Performance of anaerobic digestion of chicken manure under gradually elevated organic loading rates, International Journal of Environmental Research and Public Health 16 (2019) 2239. https://doi.org/10.3390/ijerph16122239.

C. Lü, Y. Shen, C. Li, N. Zhu, H. Yuan, Redox-Active biochar and conductive graphite stimulate methanogenic metabolism in anaerobic digestion of waste-activated sludge: Beyond direct interspecies electron transfer, ACS Sustainable Chemistry & Engineering 8 (2020) 12626–12636. https://doi.org/10.1021/acssuschemeng.0c04109.

R. Rajagopal, D.1. Massé, G. Singh, A critical review on inhibition of anaerobic digestion process by excess ammonia, Bioresource Technology 143 (2013) 632–641. https://doi.org/10.1016/j.biortech.2013.06.030.

X. Meng, D. Yu, Y. Wei, Y. Zhang, Q. Zhang, Z. Wang, J. Liu, Y. Wang, Endogenous ternary pH buffer system with ammonia carbonates-VFAs in high solid anaerobic digestion of swine manure: An alternative for alleviating ammonia inhibition, Process Biochemistry 69 (2018) 144–152. https://doi.org/10.1016/j.procbio.2018.03.015.

D. Cudjoe, M.S. Han, A.P. Nandiwardhana, Electricity generation using biogas from organic fraction of municipal solid waste generated in provinces of China: Techno-economic and environmental impact analysis, Fuel Processing Technology 203 (2020) 106381. https://doi.org/10.1016/j.fuproc.2020.106381.

X. Wang, G. Yang, Y. Feng, G. Ren, X. Han, Optimizing feeding composition and carbon–nitrogen ratios for improved methane yield during anaerobic co-digestion of dairy, chicken manure and wheat straw, Bioresource Technology 120 (2012) 78–83. https://doi.org/10.1016/j.biortech.2012.06.058.

J. Li, L. Wei, Q. Duan, G. Hu, G. Zhang, Semi-continuous anaerobic co-digestion of dairy manure with three crop residues for biogas production, Bioresource Technology 156 (2014) 307–313. https://doi.org/10.1016/j.biortech.2014.01.064.

W. Li, M.A.H. Siddhu, F.R. Amin, Y. He, R. Zhang, G. Liu, C. Chen. Methane production through anaerobic co-digestion of sheep dung and waste paper, Energy Conversion and Management 156 (2018) 279–287. https://doi.org/10.1016/j.enconman.2017.08.002.

G. Ma, P. Ndegwa, J.H. Harrison, Y. Chen. Methane yields during anaerobic co-digestion of animal manure with other feedstocks: A meta-analysis, Science of The Total Environment 728 (2020)138224. https://doi.org/10.1016/j.scitotenv.2020.138224.

L. Meng, K. Jin, R. Yi, M. Chen, J. Peng, Y. Pan, Enhancement of bioenergy recovery from agricultural wastes through recycling of cellulosic alcoholic fermentation vinasse for anaerobic co-digestion, Bioresource Technology 311 (2020)123511. https://doi.org/10.1016/j.biortech.2020.123511.

E.K., Orhorhoro, E.E. Lindsay, J.O. Oyejide, Analysis and Evaluation of a Three-Stage Anaerobic Digestion Plant for Management of Biodegradable Municipal Solid Waste, International Journal of Engineering Research in Africa 60 (2022) 75-87. https://doi:10.4028/p-a24obb.

C.B. Arenas, W. Meredith, C.E. Snape, X. Gómez, J.F. González, JE.J. Martínez. Effect of char addition on anaerobic digestion of animal by-products: Evaluating biogas production and process performance, Environmental Science and Pollution Research 27 (2020) 24387–24399. https://doi.org/10.1007/s11356-020-08828-8.

D.C. Tápparo, A. Viancelli, A.C. do Amaral, G. Fongaro, R.L.R. Steinmetz, M.E. Magri, C.R. Monte-Barardi, A. Kunz. Sanitary effectiveness and biogas yield by anaerobic co-digestion of swine carcasses and manure, Environmental Technology 41 (2020) 682–690. https://doi.org/10.1080/09593330.2018.1508256.

J. Xu, H. Lin, K. Sheng. Effects of hydrothermal pretreatment and hydrochar addition on the performance of pig carcass anaerobic digestion, Frontiers Microbiology 12 (2021) 62235. https://doi.org/10.3389/fmicb.2021.622235.

J. Procházka, P. Dolejš, J. Máca, M. Dohányos, Stability and inhibition of anaerobic processes caused by insufficiency or excess of ammonia nitrogen, Applied Microbiology and Biotechnology 93 (2012) 439–447. https://doi.org/10.1007/s00253-011-3625-4.

R.E. Hernández-Regalado, J. Häner, D. Baumkötter, L. Wettwer, E. Brügging, J. Tränckner, Continuous co-digestion of agro-industrial mixtures in laboratory scale expanded granular sludge bed reactors, Applied Sciences 12 (2022) 2295. https://doi.org/10.3390/app12052295.

Y. Zhao, N. Bourgougnon, J.L. Lanoisellé, T. Lendormi, Biofuel production from seaweeds: A comprehensive review, Energies 15 (2022) 9395. https://doi.org/10.3390/en15249395.

K.A. Fakoya, F.G. Owodeinde, S.L. Akintola, M.A. Adewolu, M.A. Abass, P.E.N. Ndimele, An exposition on potential seaweed resources for exploitation, culture and utilization in West Africa: a case study of Nigeria, Journal of Fisheries and Aquatic Science 6 (2011)37–47. https://doi.org/10.3923/jfas.2011.37.47.

B.B. Solarin, D.A. Bolaji, O.S. Fakayode, R.O. Akinnigbagbe, Impacts of an invasive seaweed Sargassum hystrix var. fluitans (Børgesen 1914) on the fisheries and other economic implications for the Nigerian coastal waters, IOSR Journal of Agriculture and Veterinary Science 7 (2014) 01–06.

J.L. Pelegrin, and J. Pena-Izquierdo, Eastern boundary currents off North-West Africa. In: Valdes L, Deniz-Gonzalez I (eds) Oceanographic and biological features in the Canary Current Large Marine Ecosystem. IOCUNESCO, Paris, IOC Technical Series 115 (2015) 81–92.

V. Hormann, R. Lumpkin, G.R. Foltz. Interannual North Equatorial Countercurrent variability and its relation to tropical Atlantic climate modes, Journal of Geophysical Research: Oceans 117 (2012) 1–17. https://doi.org/10.1029/2011JC007697.

E. Aparicio, R.M. Rodríguez-Jasso, A. Lara, A. Loredo-Treviño, C.N. Aguilar, E.T. Kostas, H.A. Ruiz, Chapter 15—Biofuels production of third generation biorefinery from macroalgal biomass in the mexican context: An overview. In Sustainable Seaweed Technologies; Torres, M.D., Kraan, S., Dominguez, H., Eds.; Advances in Green and Sustainable Chemistry; Elsevier: Amsterdam, The Netherlands. (2020) 393–446. ISBN 978-0-12-817943-7.

H. Chen, Seaweeds for biofuels production progress and perspectives, Renew. Renewable and Sustainable Energy Reviews 11 (2015) 427–437. https://doi.org/10.1016/j.rser.2015.03.086.

N. Bourgougnon, A. Gervois, Les Algues Marines: Biologie, Écologie et Utilisation; Ellipses: Paris, France, 2021, ISBN 978-2-340-05654-1

S. Kumar, D. Sahoo, I. Levine, Assessment of nutritional value in a brown seaweed sargassum wightii and their seasonal variations, Algal Research 9 (2015) 117–125. https://doi.org/10.1016/j.algal.2015.02.024.

G. Jard, H. Marfaing, H. Carrère, J.P. Delgenes, J.P. Steyer, C. Dumas, French brittany seaweeds screening: Composition and methane potential for potential alternative sources of energy and products, Bioresour. Technol. 144 (2013) 492–498. https://doi.org/10.1016/j.biortech.2013.06.114.

A.I. Usov, G.P. Smirnova, N.G. Klochkova, Polysaccharides of Algae: 55. Polysaccharide Composition of Several Brown Algae from Kamchatka, Russian Journal of Bioorganic Chemistry 27 (2001) 395–399. https://doi.org/10.1023/A:1012992820204.

B.S. Padam, F.Y. Chye, Chapter 2—Seaweed Components, Properties, and Applications. In Sustainable Seaweed Technologies; Torres, M.D., Kraan, S., Dominguez, H., Eds.; Advances in Green and Sustainable Chemistry; Elsevier: Amsterdam, The Netherlands, (2020) 33–87. ISBN 978-0-12-817943-7.

F. Monlau, C. Sambusiti, A. Barakat, M. Quéméneur, E. Trably, J.P. Steyer, H. Carrère, Do furanic and phenolic compounds of lignocellulosic and algae biomass hydrolyzate inhibit anaerobic mixed cultures? A comprehensive review, Biotechnology Advances 32 (2014) 934–951. https://doi.org/10.1016/j.biotechadv.2014.04.007.

B.S. Padam, F.Y. Chye, Chapter 2—Seaweed Components, Properties, and Applications. In Sustainable Seaweed Technologies; Torres, M.D., Kraan, S., Dominguez, H., Eds.; Advances in Green and Sustainable Chemistry; Elsevier: Amsterdam, The Netherlands. (2020) 33–87. ISBN 978-0-12-817943-7

A. Jensen, Present and future needs for algae and algal products, Hydrobiologia 260 (1993) 15–23. https://doi.org/10.1007/BF00048998.

Y.N. Barbot, H. Al-Ghaili, R. Benz, A review on the valorization of macroalgal wastes for biomethane production, Marine Drugs 14 (2016) 120. https://doi.org/10.3390/md14060120.

J. Singh, S. Gu, Commercialization potential of microalgae for biofuels production, Renewable and Sustainable Energy Reviews 14 (2010) 2596–2610. https://doi.org/10.1016/j.rser.2010.06.014.

K.T. Bird, D.P. Chynoweth, D.E. Jerger, Effects of marine algal proximate composition on methane yields, Journal of Applied Phycology 2 (1990) 207–213. https://doi.org/10.1007/BF02179777.

O.O. Osita, U.G. Lawan, The optimum mesophilic temperature of batch process biogas production from animal-based wastes, Research Journal of Applied Sciences, Engineering and Technology 8(16) (2014) 1772-1776. http://dx.doi.org/10.19026/rjaset.8.1163.

M.A. Rahman, R. Shahazi, S.N.B. Nova, M.R. Uddin, M.S. Hossain, A. Yousuf. Biogas production from anaerobic co-digestion using kitchen waste and poultry manure as substrate—part 1: Substrate ratio and effect of temperature, Biomass Conversion and Biorefinery 13 (2021) 1-11. https://doi.org/10.1007/s13399-021-01604-9.

P.O. Ebunilo, E.K. Orhorhoro, V. Oboh, P.U. Onochie. Effect of temperature on biogas yields using south-south nigeria as a case study, International Journal of Technology Enhancements and Emerging Engineering Research 4(6) (2016) 50-54.

H.K. Ahn, M.C. Smith, S.L. Kondrad, J.W. White. Evaluation of biogas production potential by dry anaerobic digestion of switchgrass–animal manure mixtures, Applied Biochemistry and Biotechnology 160 (2010) 965–975. https://doi.org/10.1007/s12010-009-8624-x.

F. Wang, M. Pei, L. Qiu, Y. Yao, C. Zhang, H. Qiang. Performance of anaerobic digestion of chicken manure under gradually elevated organic loading rates, International Journal of Environmental Research and Public Health 16(2019) 2239. https://doi.org/10.3390/ijerph16122239.

P. Mahato, B. Goyette, M. Rahaman, R. Rajagopal. Processing high-solid and high-ammonia rich manures in a two-stage (liquid-solid) low-temperature anaerobic digestion process: start-up and operating strategies, Bioengineering 7 (2020) 80. https://doi.org/10.3390/bioengineering7030080.

Z. Ning, J. Ji, Y. He, Y. Huang, G. Liu, C. Chen. Effect of lipase hydrolysis on biomethane production from swine slaughterhouse waste in China, Energy Fuels 30(2016) 7326–7330. https://doi.org/10.1021/acs.energyfuels.6b01097.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Progress in Energy and Environment

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.