Investigation on the Potential of Bioethanol Synthesis from Honeydew Melon Rind

Keywords:

Honeydew melon, Lignocellulosic biomass, BioethanolAbstract

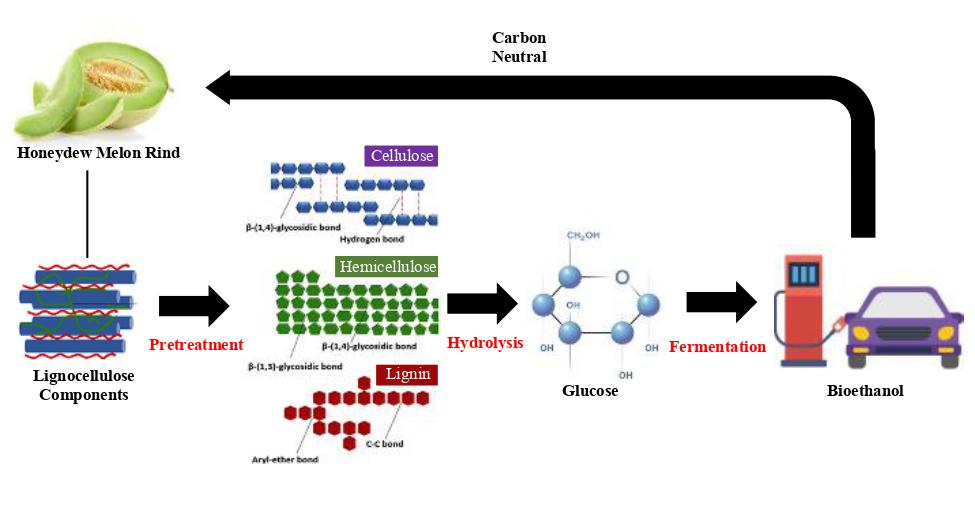

Honeydew melon rind is an abundant and low-cost fruit waste, which holds potential for glucose and eventual bioethanol synthesis. In this study, alkaline pre-treatment was introduced to break down the lignin structure before conducting acid hydrolysis to further breakdown the cellulosic components into glucose. The functional group of the pre-treated and raw samples were analysed using Fourier-Transform Infrared (FTIR) spectroscopy to evaluate the effectiveness of alkaline pre-treatment in lignin removal. Alkaline pre-treatment was found to effective in lignin removal from the rind, thus, improving the accessibility of cellulose and hemicellulose for acid hydrolysis. Using response surface methodology (RSM) based on the central composite design, a maximum glucose concentration of 9.847% w/v was obtained using an acid concentration of 6% w/v, a reaction temperature of 75°C for 60 minutes. The hydrolysate which was fermented using the Saccharomyces cerevisiae (baker’s yeast) revealed the presence of ethanol as the major product with some traces of impurities. This shows that honeydew melon rind has the potential as lignocellulosic biomass source for bioethanol synthesis.

References

M. Chen, H. Zhang, W. Liu, W. Zhang, The global pattern of urbanization and economic growth: Evidence from the last three decades, PLOS ONE. 9(8) (2014) 1–15. https://doi.org/10.1371/journal.pone.0103799.

R. Cervero, Transport infrastructure and the environment in the global south: Sustainable mobility and urbanism, Journal of Urban and Planning Development. 25(3) (2014) 174–191. https://doi.org/10.5614/jpwk.2015.25.3.1.

L. Li, B.P.Y. Loo, Alternative and transitional energy sources for urban transportation, Current Sustainable or Renewable Energy Reports 1(1) (2014) 19–26. https://doi.org/10.1007/s40518-014-0005-6.

A. García-olivares, J. Solé, O. Osychenko, Transportation in a 100% renewable energy system, Energy Conversion and Management. 158 (2018) 266–285. https://doi.org/10.1016/j.enconman.2017.12.053.

N. Khan, E. Kalair, N. Abas, A.R. Kalair, A. and Kalair, Energy transition from molecules to atoms and photons, Engineering Science and Technology, an International Journal. 22(1) (2019) 185–214. https://doi.org/10.1016/j.jestch.2018.05.002.

B. Hitesh, S. Revankar, Nuclear Hydrogen Production, in: Storage and Hybridization of Nuclear Energy, 1st ed., Academic Press, United States, 2019.

G. Balachandar, N. Khanna, D. Das, Biohydrogen Production from Organic Wastes by Dark Fermentation, in: Biohydrogen, 1st ed., Elsevier B.V., 2013.

L. Matsakas, D. Kekos, M. Loizidou, P. Christakopoulos, Utilization of household food waste for the production of ethanol at high dry material content, Biotechnology for Biofuels. 7(1) (2014) 1–9. https://doi.org/10.1186/1754-6834-7-4.

P.R. Sood, Bioethanol - A viable answer to India’s surging energy needs, International Journal of Economics and Management Engineering. 6(8) (2012) 1357–1361.

N. Sarkar, S.K. Ghosh, S. Bannerjee, K. Aikat, Bioethanol production from agricultural wastes: An overview, Renewable Energy. 37(1) (2012) 19–27. https://doi.org/10.1016/j.renene.2011.06.045.

K.M. Lee, K.N. Ng, Effect of ultrasonication in Organosolv pretreatment for enhancement of fermentable sugars recovery from palm oil empty fruit bunches, Progress in Energy and Environment. 11 (2019) 15-23. https://www.akademiabaru.com/submit/index.php/progee/article/view/1059.

P.M. Rolim, L. Mont, A. Jucá, G.R. De, Melon by-products: Biopotential in human health and food processing, Food Reviews International. (2019) 1–24. https://doi.org/10.1080/87559129.2019.1613662.

R.B. Nair, P.R. Lennartsson, M.J. Taherzadeh, Bioethanol Production from Agricultural and Municipal Wastes, in: J. Wong, R. Tyagi, A. Pandey, (eds) Current Developments in Biotechnology and Bioengineering, 1st ed., Elsevier B.V., New York, 2017: pp. 157–190.

V.K. Joshi, A. Kumar, V. Kumar, Antimicrobial, antioxidant and phyto-chemicals from fruit and vegetable wastes: A review, International Journal of Food Fermentation Technology. 2(2) (2012) 123–136.

E.G. Sarojini Daniel, Biology Education and Research in a Changing Planet, 25th ed., Springer, Singapore, 2015.

R. Salehi, A. Taghizadeh-alisaraei, F. Shahidi, A. Jahanbakhshi, Potentiometric of bioethanol production from cantaloupe waste (Magassi Neishabouri Cultivar), Journal of the Saudi Society of Agricultural Sciences. 19(1) (2020) 51–55. https://doi.org/10.1016/j.jssas.2018.05.006.

S.V. Bhandari, A. Panchapakesan, N. Shankar, H.G.A. Kumar, Production of bioethanol from fruit rinds by saccharification and fermentation. International Journal of Scientific Research Engineering and Technology. 2(6) (2013) 362–365.

V. Balan, Current challenges in commercially producing biofuels from lignocellulosic biomass, International Scholarly Research Notices. 2014 (2014) Article ID 463074. https://doi.org/10.1155/2014/463074.

A. Buši?, N. Mardetko, S. Kundas, G. Morzak, H. Belskaya, M.I. Šantek, D. Komes, S. Novak, B. Šantek, Bioethanol production from renewable raw materials and its separation and purification: A review, Food Technology and Biotechnology. 56(3) (2018) 289–311. https://doi.org/10.1016/10.17113/ftb.56.03.18.5546.

F. Scott, J. Quintero, M. Morales, R. Conejeros, C. Cardona, G. Aroca, Process design and sustainability in the production of bioethanol from lignocellulosic materials, Electronic Journal of Biotechnology, 16(3) (2013).

R. Muktham, S.K. Bhargava, S. Bankupalli, A.S. Ball, A review on 1st and 2nd generation bioethanol production - recent progress, Journal of Sustainable Bioenergy Systems. 6 (2016) 72–92. https://doi.org/10.4236/jsbs.2016.63008.

R. Cutzu, L. Bardi, L. Production of bioethanol from agricultural wastes using residual thermal energy of a cogeneration plant in the distillation phase, Fermentation. 3(2) (2017) 24. https://doi.org/10.3390/fermentation3020024.

H.H. Lee, I. Ismail, K.A. Mustafa, M.A. Suhaimi, Effect of different drying conditions on proximate compositions of red- and yellow-fleshed watermelon rind powders, Journal of Agrobiotechnology. 7 (2016) 1–12.

H. Jung, Y.J. Lee, W.B. Yoon, Effect of moisture content on the grinding process and powder properties in food: A review, Process. 6(6) (2018) 69. https://doi.org/10.3390/pr6060069.

Y. Cheng, Y. Zheng, C.W. Yu, T.M. Dooley, B.M. Jenkins, J.S. Vandergheynst, Evaluation of high solids alkaline pretreatment of rice straw, Appl Biochem Biotechnol. 162(6) (2010) 1768–1784. https://doi.org/10.1007/s12010-010-8958-4.

E.M. Karp, B.S. Donohoe, M.H.O. Brien, P.N. Ciesielski, A. Mittal, M.J. Biddy, G. Beckham, Alkaline pretreatment of corn stover: Bench-scale fractionation and stream characterization, Sustainable Chemical Engineering. 2(6) (2014) 1481–1491. https://doi.org/10.1021/sc500126u.

K. Wunna, K. Nakasaki, J.L. Auresenia, L.C. Abella, P.A.D. Gaspillo, Effect of alkali pretreatment on removal of lignin from sugarcane bagasse, Chemical Engineering Transactions. 56 (2017) 1831–1836. https://doi.org/10.3303/CET1756306.

E.S. Lopes, K.M.C. Dominices, M.S. Lopes, L.P. Tovar, Enzymatic hydrolysis exploration and fermentation: Acid pretreatment and delignification in sugarcane bagasse for 2G ethanol production, Chemical Engineering Transactions. 57 (2017) 151–156. https://doi.org/10.3303/CET1757026.

L. Ma, Y. Cui, R. Cai, X. Liu, C. Zhang, D. Xiao, D. Optimization and evaluation of alkaline potassium permanganate pretreatment of corncob, Bioresource Technology. 180 (2015) 1–6. https://doi.org/10.1016/j.biortech.2014.12.078.

N.S. Hassan, K.H. Badri, Lignin recovery from alkaline hydrolysis and glycerolysis of oil palm fiber, AIP Conference Proceedings. 1614 (2015) 433–438. https://doi.org/10.1063/1.4895236.

A. Wawro, J. Batog, W. Gieparda, Chemical and enzymatic treatment of hemp biomass for bioethanol production, Applied Sciences. 9(24) (2019) 5438. https://doi.org/10.3390/app9245348.

J. Segal, A. Cedarman, D. MacIsaac, Demonstrations in Optics, Physical Buffalo Education.

P. Phitsuwan, C. Permsriburasuk, S. Baramee, T. Teeravivattanakit, K. Ratanakhanokchai, Structural Analysis of alkaline pretreated rice straw for ethanol production, International Journal of Polymer Science. 2017 (2017) 1–9. https://doi.org/10.1155/2017/4876969.

S. Sharma, V. Sharma, A. Kuila, Cellulase production using natural medium and its application on enzymatic hydrolysis of thermo chemically pretreated biomass, 3 Biotech. 6(2) (2016) 139. https://doi.org/10.1007/s13205-016-0465-z.

R. Ramos-gonzalez, M. Aguilar, A. Aguilera, A. Ilyina, G. Michelena, Comparison of physicochemical pretreatments of banana peels for bioethanol production, Food Science and Biotechnology. 26 (2017) 993–1001. https://doi.org/10.1007/s10068-017-0128-9.

A.H. Sebayang, H.C. Ong, H.H. Masjuki, S. Dharma, A.S. Silitonga, H.B. Aditiya, A prospective of bioethanol production from biomass as alternative fuel for spark ignition engine, RSC Advances. 6(13) (2016) 14964–14992. https://doi.org/10.1039/C5RA24983J.

H.I. Hamouda, H.N. Nassar, H.R. Madian, S.S.A. Amr, N.S. El-gendy, Response surface optimization of bioethanol production from Sugarcane Molasses by Pichia veronae Strain HSC-22, Biotechnology Research International. 2015 (2015) Article ID 905792. https://doi.org/10.1155/2015/905792.

A. Ayoola, O. Adeeyo, V. Efeovbokhan, Optimum hydrolysis conditions of Cassava starch for glucose production, International Journal of Advanced Research in IT and Engineering. 2(1) (2013) 93–101.

P. Moodley, E.B. Gueguim, Bioethanol production from sugarcane leaf waste: Effect of various optimized pretreatments and fermentation conditions on process kinetics, Biotechnology Reports. 22 (2019) e00329. https://doi.org/10.1016/j.btre.2019.e00329.

W. Jonglertjunya, W. Makkhanon, Dilute acid hydrolysis of Sugarcane Bagasse for Butanol fermentation, Chiang Mai Journal of Science. 40(1) (2014) 60–70.

V.V. Goud, R. Timung, N.N. Deshavath, V.V. Dasu, Effect of subsequent dilute acid and enzymatic hydrolysis on reducing sugar production from sugarcane bagasse and spent Citronella biomass. 2016 (2016) Article ID 8506214. https://doi.org/10.1155/2016/8506214.

R. Aguilar, J.A. Ram, Kinetic study of the acid hydrolysis of sugar cane bagasse, Journal of Food Engineering. 55(4) (2012) 309–318. https://doi.org/10.1016/S0260-8774(02)00106-1.

R.S. Peterson, C.G. Hill, C.H. Amundson, Effects of temperature on the hydrolysis of lactose by immobilized P-Galactosidase in a capillary bed reactor. Biotechnology and Bioengineering, 34 (1989) 429–43. https://doi.org/10.1002/bit.260340403.

X. Tian, J. Li, B. Wang, K. Chen, J. Zeng, J. Xu, W. Gao, Optimization of pretreatment and alkaline cooking of wheat straw on its pulpability using response surface methodology, Bioresources. 13 (2018) 27–42.

A. Ajani, S. Agarry, O. Agbede, A comparative kinetic study of acidic hydrolysis of wastes cellulose from agricultural derived biomass, Journal of Applied Sciences and Environmental Management. 15(4), pp. 531–537.

V. Bakare, A. Salami, B. Onusiriuka, J. Appah, B. Benjamin, Ethanol production from lignocellulosic materials by fermentation process using yeast, Journal of Applied Sciences and Environmental Management. 23(5) (2019) 875–882.

D. Styarini, Y. Aristiawan, F. Aulia, H. Abimanyu, Y. Sudiyani, Determination of organic impurities in lignocellulosic bioethanol product by determination of organic impurities in lignocellulosic bioethanol product by GC-FID, Physics Procedia. 32 (2013) 153–159. https://doi.org/10.1016/j.egypro.2013.05.020.

H.H. Abe, T.S. Hinbo, T.Y. Amamoto, S.S. Ato, H.S. Himada, K.S. Akaki, Chemical analysis of impurities in diverse bioethanol samples, Journal of the Japan Petroleum Institute. 56(6) (2013) 414–422. https://doi.org/10.1627/jpi.56.414.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Progress in Energy and Environment

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.