Potential Use of Rise Husk as Filler in Poly Lactic Acid Bio-composite: Mechanical Properties, Morphology and Biodegradability

Keywords:

Rise husk, Agricultural waste, Bio-polybag, Poly lactic acidAbstract

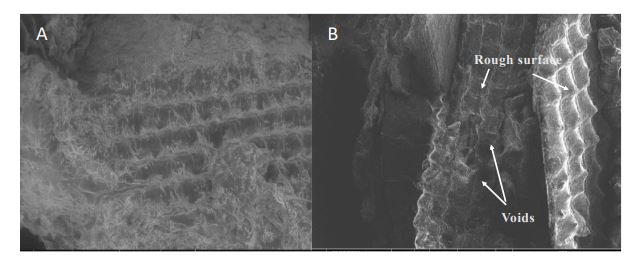

About 408,000 metric tonnes of rice husk are produced annually yet not utilised fully. In agriculture, biodegradable plastics are desirable alternative to the current black low densities poly(ethylene) plastic. Therefore, a research on bio-polybag is needed to be investigated their properties of obtained polybag in terms of mechanical properties, surface structure, and biodegradability. The biomasses studied in this research are rice husk (RH) due to their abundance in Malaysia, and polylactic acid were used to mix with the biomasses in different compositions (10%, 30%, 50%, 70% and 90%). Three main tests including tensile strength test, aging test and Scanning Election Microscopy (SEM) were taken place to study the properties. As a result, 30% rice husk: 70% PLA is the best among the ratio, in terms of lower tensile strength, higher elasticity, and shows bigger void and gap. At ratio of 30% rice husk and 70% PLA has the tensile strength of 11.3 MPa, tensile modulus at 322.12 MPa, elongation at break at 3.508%, decomposition rate of 3.3% and SEM analysis showed many gaps yet with maximum used of biomass material. Hence, ratio of 30% rice husk and 70% PLA is the most suitable biomass to use as biodegradable polybag.