Effect of Cylinder Gap Ratio on The Wake of a Circular Cylinder Enclosed by Various Perforated Shrouds

DOI:

https://doi.org/10.37934/cfdl.13.4.5168Keywords:

Perforated shroud, vortex shedding, passive controlAbstract

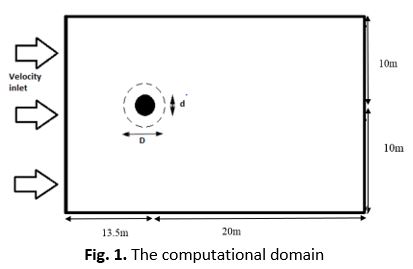

Flow over bluff bodies produces vortex shedding in their wake regions, leading to structural failure from the flow-induced forces. In this study, a passive flow control method was explored to suppress the vortex shedding from a circular cylinder that causes many problems in engineering applications. Perforated shrouds were used to control the vortex shedding of a circular cylinder at Reynolds number, Re = 200. The shrouds were of non-uniform and uniform holes with 67% porosity. The spacing gap ratio between the shroud and the cylinder was set at 1.2, 1.5, 2, and 2.2. The analysis was conducted using ANSYS Fluent using a viscous laminar model. The outcomes of the simulation of the base case were validated with existing studies. The drag coefficient, Cd, lift coefficient, Cl and the Strouhal number, St, as well as vorticity contours, velocity contours, and pressure contours were examined. Vortex shedding behind the shrouded cylinders was observed to be suppressed and delayed farther downstream with increasing gap ratio. The effect was significant for spacing ratio greater than 2.0. The effect of hole types: uniform and non-uniform holes, was also effective at these spacing ratios for the chosen Reynolds number of 200. Specifically, a spacing ratio of 1.2 enhanced further the vortex intensity and should be avoided.

References

Dehkordi, Behzad Ghadiri, Hesam Sarvghad Moghaddam, and Hamed Houri Jafari. "Numerical simulation of flow over two circular cylinders in tandem arrangement." Journal of Hydrodynamics 23, no. 1 (2011): 114-126. https://doi.org/10.1016/S1001-6058(10)60095-9

Giosan, Ioan, and P. Eng. "Vortex shedding induced loads on free standing structures." Structural Vortex Shedding Response Estimation Methodology and Finite Element Simulation 42 (2013).

Galbraith, R. A. McD. "Flow pattern around a shrouded cylinder at Re= 5× 103." Journal of Wind Engineering and Industrial Aerodynamics 6, no. 3-4 (1980): 227-242. https://doi.org/10.1016/0167-6105(80)90003-3

Triantafyllou, Michael S., Rémi Bourguet, Jason Dahl, and Yahya Modarres-Sadeghi. "Vortex-induced vibrations." In Springer Handbook of Ocean Engineering, pp. 819-850. Springer, Cham, 2016. https://doi.org/10.1007/978-3-319-16649-0_36

Cottet, Georges-Henri, Roland Hildebrand, Petros Koumoutsakos, Chloé Mimeau, Iraj Mortazavi, and Philippe Poncet. "Passive and active flow control using vortex methods." In 6th International Conference on Vortex Flows and Vortex Models. 2014.

Every, M. J., R. King, and D. S. Weaver. "Vortex-excited vibrations of cylinders and cables and their suppression." Ocean Engineering 9, no. 2 (1982): 135-157. https://doi.org/10.1016/0029-8018(82)90010-5

Boorsma, K., Xin Zhang, N. Molin, and L. C. Chow. "Bluff body noise control using perforated fairings." AIAA Journal 47, no. 1 (2009): 33-43. https://doi.org/10.2514/1.32766

Ikeda, Mitsuru, and Takehisa Takaishi. "Perforated pantograph horn aeolian tone suppression mechanism." Quarterly Report of RTRI 45, no. 3 (2004): 169-174. https://doi.org/10.2219/rtriqr.45.169

Kleissl, Kenneth, and C. T. Georgakis. "Aerodynamic control of bridge cables through shape modification: A preliminary study." Journal of Fluids and Structures 27, no. 7 (2011): 1006-1020. https://doi.org/10.1016/j.jfluidstructs.2011.04.012

Osrin, M. F., A. M. Azmi, H. Yusoff, and N. A. Razak. "Effect of shroud hole on the force characteristics of a circular cylinder." International Journal of Engineering and Advanced Technology 9, no. 1 (2019): 5929-5935. https://doi.org/10.35940/ijeat.A3030.109119

Misman, M. R. A., A. M. Azmi, Z. A. Kamarulbaharin, and A. H. A. Hamid. "The Effect of Slat Opening on Vortex Shedding Behind a Circular Cylinder." International Journal of Recent Technology and Engineering (IJRTE) 8, no. 4 (2019): 6879-6885. https://doi.org/10.35940/ijrte.D5210.118419

Yao, Jianfeng, Wenjuan Lou, Guohui Shen, Yong Guo, and Yuelong Xing. "Influence of inflow turbulence on the flow characteristics around a circular cylinder." Applied Sciences 9, no. 17 (2019): 3595. https://doi.org/10.3390/app9173595

Sudalaimuthu, Vignesh K., and Xiaofeng Liu. "An Experimental Investigation of the Effect of Surface Perforation on Unsteady Aerodynamic Force Reduction for a Hollow Cylinder." In AIAA Scitech 2019 Forum, p. 1137. 2019. https://doi.org/10.2514/6.2019-1137

Lin, Li-ming, Xing-fu Zhong, and Ying-xiang Wu. "Effect of peak perforation on flow past a conic cylinder at Re= 100: drag, lift and Strouhal number." China Ocean Engineering 31, no. 3 (2017): 330-340. https://doi.org/10.1007/s13344-017-0039-9

Azmi, Azlin Mohd, and Tongming Zhou. "Effect of screen geometry on the vortex formation behind a circular cylinder." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 44, no. 1 (2018): 47-54.

Steiros, K., K. Kokmanian, N. Bempedelis, and M. Hultmark. "The effect of porosity on the drag of cylinders." Journal of Fluid Mechanics 901 (2020): R2. https://doi.org/10.1017/jfm.2020.606

Meneghini, J. R., F. Saltara, C. L. R. Siqueira, and J. A. Ferrari Jr. "Numerical simulation of flow interference between two circular cylinders in tandem and side-by-side arrangements." Journal of Fluids and Structures 15, no. 2 (2001): 327-350. https://doi.org/10.1006/jfls.2000.0343

Ding, H., C. Shu, K. S. Yeo, and D. Xu. "Numerical simulation of flows around two circular cylinders by mesh?free least square?based finite difference methods." International Journal for Numerical Methods in Fluids 53, no. 2 (2007): 305-332. https://doi.org/10.1002/fld.1281