Temperature Minimization on the Substrate of a Heat Sink By Rib-Groove Microchannel Heat Sink with Effective Energy Consumption: Groove Geometry Parameter Effects

Keywords:

rib-groove microchannel heat sink, substrate temperature, pumping power consumption, energy consumptionAbstract

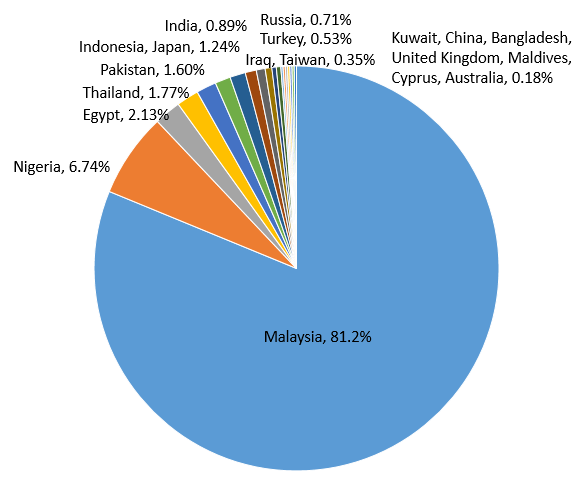

With the unpredicted increment of power density in Microelectromechanical systems (MEMS) device, an effective cooling technique like micro-cooling method is required to ensure temperature of the device not exceeds or near to the allowable temperature for semiconductor component (Allowable temperature < 358.15 K). Microchannel heat sink is one of the best candidate among micro-cooling method which can meet a cooling demand for current electronic devices. The temperature of a substrate of microchannel heat sink is very important because the substrate directly attaches to the electronic components. By increasing a mass flowrate in a conventional microchannel heat sink (straight channel design) in order to reduce the substrate temperature is not an effective method because it reduces the effective energy consumption. So in this paper, Rib-groove microchannel heat sink design is proposed in order to the minimize the substrate temperature with effective energy consumption. In the present study, the effect of triangular groove geometry parameter was analysed numerically for the Re number ranging between 100 to 800. The result showed that, Rib-groove microchannel heat sink (TC-RR MCHS) with triangular cavities pitch location of 140 ?m (CV3) obtained the lowest average substrate temperature, Tb, ave for all Re number. Besides that, the TC-RR MCHS with CV3 design only required 1.82 mW of pumping power while the straight microchannel heat sink (CR MCHS) required 14.94 mW of pumping power in order to achieve the lowest average substrate temperature in the CR MCHS. Means that, the proposed design saved the energy consumption up to 87.8%.