Mixing Performance of Anchor and Helical Stirrer Blades for Viscous Fluid Applications

DOI:

https://doi.org/10.37934/cfdl.13.1.5871Keywords:

Mixing, Stirrer blades, Oils and greases, CFDAbstract

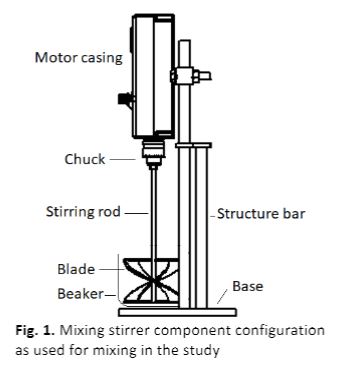

Mixing performance is critical as it may influence the quality of the mixture and operation cost. In a viscous fluid application, the torque required to sustain the high viscosity is very important as it will affect the selection of motor power and cost. The final product of the mixing process is critically influenced by the blade design. The objective of this work is to study the mixing behaviour and the performance of different stirrer blade designs. Two different types of blades were designed and studied to determine how their distinct design features affected flow characteristics in a stirred tank. The liquid viscosity during the formation of grease is taken into account in the determination of viscous force. Fluid flow vector shows that the helical blade efficiently creates a more homogenous uniform mixing. It was found that the helical blade produced 0.25 Nm of torque, whilst the anchor blade produced 0.28 Nm of torque. These values are comparable with the calculation with 8 % error. Therefore, the helical blade can be used as an alternative for the anchor blade due to an efficient mixing process at a faster time and lower power consumption.

References

Zhang, Pan, Guanghui Chen, Jihai Duan, and Weiwen Wang. "Mixing characteristics in a vessel equipped with cylindrical stirrer." Results in Physics 10 (2018): 699-705. https://doi.org/10.1016/j.rinp.2018.07.024

Isabela, M.P., and Leandro, S.O. ''CFD Modelling and Simulation of Transesterification Reactions of Vegetable Oils With an Alcohol in Baffled Stirred Tank Reactor.'' Applied Mechanics and Materials 390 (2013): 86-90. https://doi.org/10.4028/www.scientific.net/AMM.390.86

Jaszczur, Marek, Anna M?ynarczykowska, and Luana Demurtas. "Effect of Impeller Design on Power Characteristics and Newtonian Fluids Mixing Efficiency in a Mechanically Agitated Vessel at Low Reynolds Numbers." Energies 13, no. 3 (2020): 640. https://doi.org/10.3390/en13030640

Tsui, Yeng-Yung, and Yu-Chang Hu. "Flow characteristics in mixers agitated by helical ribbon blade impeller." Engineering Applications of Computational Fluid Mechanics 5, no. 3 (2011): 416-429. https://doi.org/10.1080/19942060.2011.11015383

Ameur, Houari. "Energy efficiency of different impellers in stirred tank reactors." Energy 93 (2015): 1980-1988. https://doi.org/10.1016/j.energy.2015.10.084

Tsz-Chung Mak, A. "Solid-liquid mixing in mechanically agitated vessels." PhD. University of London (1992).

Ameur, Houari. "Effect of some parameters on the performance of anchor impellers for stirring shear-thinning fluids in a cylindrical vessel." Journal of Hydrodynamics 28, no. 4 (2016): 669-675. https://doi.org/10.1016/S1001-6058(16)60671-6

Ge, Chun-Yan, Jia-Jun Wang, Xue-Ping Gu, and Lian-Fang Feng. "CFD simulation and PIV measurement of the flow field generated by modified pitched blade turbine impellers." Chemical Engineering Research and Design 92, no. 6 (2014): 1027-1036. https://doi.org/10.1016/j.cherd.2013.08.024

Peixoto, S. M. C., J. R. Nunhez, and C. G. Duarte. "Characterizing the flow of stirred vessels with anchor type impellers." Brazilian Journal of Chemical Engineering 17, no. 4-7 (2000): 925-936. https://doi.org/10.1590/S0104-66322000000400057

Gijón-Arreortúa, Ixchel, and Alberto Tecante. "Mixing time and power consumption during blending of cohesive food powders with a horizontal helical double-ribbon impeller." Journal of Food Engineering 149 (2015): 144-152. https://doi.org/10.1016/j.jfoodeng.2014.10.013

Mustafa, Adnan Ghulam, Mohd Fadhil Majnis, and Nor Azyati Abdul Muttalib. "CFD Study on Impeller Effect on Mixing in Miniature Stirred Tank Reactor." CFD Letters 12, no. 10 (2020): 15-26. https://doi.org/10.37934/cfdl.12.10.1526

Liang, Chua Bing, Akmal Nizam Mohammed, Azwan Sapit, Mohd Azahari Razali, Mohd Faisal Hushim, Amir Khalid, and Nurul Farhana Mohd Yusof. "Numerical Simulation of Aerofoil with Flow Injection at the Upper Surface." CFD Letters 12, no. 1 (2020): 98-110.

ZHANG, Minge, Lühong ZHANG, Bin Jiang, Y. I. N. Yuguo, and L. I. Xingang. "Calculation of metzner constant for double helical ribbon impeller by computational fluid dynamic method." Chinese Journal of Chemical Engineering 16, no. 5 (2008): 686-692. https://doi.org/10.1016/S1004-9541(08)60141-X

Pakzad, Leila, Farhad Ein-Mozaffari, and Philip Chan. "Using electrical resistance tomography and computational fluid dynamics modeling to study the formation of cavern in the mixing of pseudoplastic fluids possessing yield stress." Chemical Engineering Science 63, no. 9 (2008): 2508-2522. https://doi.org/10.1016/j.cep.2007.12.003

Cokljat, D., M. Slack, and S. A. Vasquez. "Progress in Comp." Fluid Dyn 6 (2006): 168-178. https://doi.org/10.1504/PCFD.2006.009494

Khopkar, A. R., G. R. Kasat, A. B. Pandit, and V. V. Ranade. "Computational fluid dynamics simulation of the solid suspension in a stirred slurry reactor." Industrial & engineering chemistry research 45, no. 12 (2006): 4416-4428. https://doi.org/10.1021/ie050941q

Zalc, J. M., E. S. Szalai, M. M. Alvarez, and F. J. Muzzio. "Using CFD to understand chaotic mixing in laminar stirred tanks." AIChE Journal 48, no. 10 (2002): 2124-2134. https://doi.org/10.1002/aic.690481004

Tatterson, Gary B. Scaleup and design of industrial mixing processes. New York: McGraw-Hill, 1994.

Torotwa, Ian, and Changying Ji. "A study of the mixing performance of different impeller designs in stirred vessels using computational fluid dynamics." Designs 2, no. 1 (2018): 10. https://doi.org/10.3390/designs2010010

Adanta, Dendy, Warjito Budiarso, Ahmad Indra Siswantara, and Aji Putro Prakoso. "Performance comparison of NACA 6509 and 6712 on pico hydro type cross-flow turbine by numerical method." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 45, no. 1 (2018): 116-127.

Ameur, Houari, and Abdellah Ghenaim. "Mixing of complex fluids in a cylindrical tank by a modified anchor impeller." ChemistrySelect 3, no. 26 (2018): 7472-7477. https://doi.org/10.1002/slct.201801047

Kamla, Youcef, Houari Ameur, Abdelkader Karas, and Mohammed Ilies Arab. "Performance of new designed anchor impellers in stirred tanks." Chemical Papers 74, no. 3 (2020): 779-785. https://doi.org/10.1007/s11696-019-00902-x

Ameur, Houari, and Youcef Kamla. "Geometrical modifications of the anchor impeller to enhance the overall performances in stirred tanks." Instal 6 (2020): 42-45. https://doi.10.36119/15.2020.6.5

Ameur, Houari, Youcef Kamla, Abdessalam Hadjeb, Ilies Mohammed Arab, and Djamel Sahel. "Data on mixing of viscous fluids by helical screw impellers in cylindrical vessels." Data in brief 8 (2016): 220-224. https://doi.org/10.1016/j.dib.2016.05.036

Ameur, Houari, Youcef Kamla, and Djamel Sahel. "Performance of helical screw impellers for mixing of viscous liquids in cylindrical reactors." ChemistrySelect 2, no. 5 (2017): 1891-1894. https://doi.org/10.1002/slct.201602072

Hadjeb, Abdessalam, Mohamed Bouzit, Youcef Kamla, and Houari Ameur. "A new geometrical model for mixing of highly viscous fluids by combining two-blade and helical screw agitators." Polish Journal of Chemical Technology 19, no. 3 (2017): 83-91. https://doi.org/10.1515/pjct-2017-0053

Aubin, Joelle, Isabelle Naude, Joël Bertrand, and Catherine Xuereb. "Blending of Newtonian and shear-thinning fluids in a tank stirred with a helical screw agitator." Chemical Engineering Research and Design 7, no. 8 (2000): 1105-1114. https://doi.org/10.1205/026387600528382

Liu, Baoqing, Manman Wang, Jingliang Liu, Luyan Qian, and Zhijiang Jin. "Experimental study on micromixing characteristics of novel large-double-blade impeller." Chemical Engineering Science 123 (2015): 641-647. https://doi.org/10.1016/j.ces.2014.11.056