Assessing the Correlation Between the Physico-Mechanical Characteristics and Microstructure of Reclaimed Carbon Dust Reinforced ABS Polymer Composite in the Extrusion Process

DOI:

https://doi.org/10.37934/armne.22.1.1125Keywords:

Reclaimed carbon dust, CFRP waste, polymer composite, strength properties, extrusion processAbstract

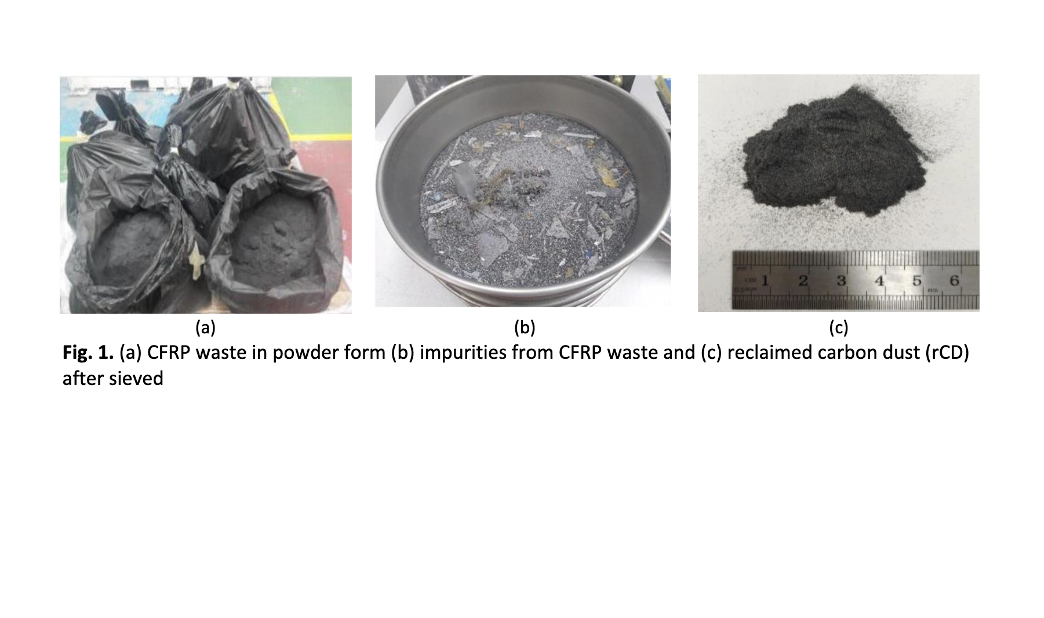

ABS polymer has limited stiffness and will fracture upon reaching this limit. Reinforcing ABS with reclaimed carbon dust (rCD) from CFRP waste, which has superior stiffness in both compression and tension, can prevent this failure. This study evaluates the impact of varying rCD filler content and screw extruder speeds on the physico-mechanical properties of the composite. rCD content ranges from 0 wt.% to 40 wt.% and screw speeds of 20 rpm and 40 rpm are used. The rCD was sieved and its quality was verified using particle size analysis (PSA), field emission scanning electron microscopy with energy dispersive X-ray (FESEM-EDX), and X-ray diffraction (XRD) before composite fabrication in a single screw extruder. The physico-mechanical properties, including tensile strength, Young’s modulus, and density, were tested using a universal testing machine (UTM) and Archimedes technique. All samples appeared undistorted prior to UTM evaluation. Results indicated that composites processed at 40 rpm with 40 wt.% rCD exhibited superior physico-mechanical properties compared to those processed at 20 rpm. Fractography of tensile fracture samples showed well-dispersed rCD within the ABS matrix, with minimal large pores at 40 rpm. Additionally, the highest tensile strength (31.48 MPa) and Young’s modulus (1.603 GPa) indicated good dispersion of rCD and strong interfacial bonding between the matrix and fiber. Thus, a 40 rpm screw speed is more effective for mixing ABS/rCD composites. In conclusion, rCD was successfully reclaimed and integrated into ABS, resulting in a composite with enhanced strength properties suitable for assistive medical device application.