Nanofluid-Infused Microchannel Heat Sinks: Comparative Study of Al2O3, TiO2, and CuO to Optimized Thermal Efficiency

DOI:

https://doi.org/10.37934/armne.19.1.112Keywords:

Thermal properties, velocity, flow characteristics, nanofluid, microchannel heatsinkAbstract

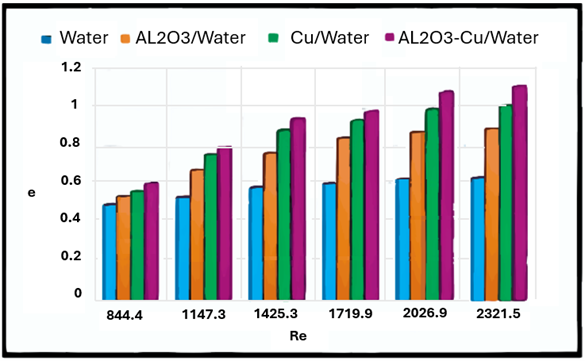

Nanofluid technology advancements have significantly improved cooling performance by utilising distributed nanoparticles, showing promise as an effective method for heat removal. These nanomaterials offer unique opportunities to cool electrical appliances. Nanofluids, akin to conventional fluids, exhibit thermophysical properties such as viscosity, specific heat, and fluid behaviour, ranging from laminar to turbulent. The thermal behavior of nanofluids is influenced not only by concentration but also by nanoparticle size, shape, material, and base fluid parameters. This study focuses on investigating the thermal behaviour and cooling efficiency within a straight single microchannel heat sink (MCHS), utilising water-based nanofluids—Al2O3, TiO2, and CuO. A series of experiments were conducted on the MCHS with varying nanoparticle concentration percentages in a rectangular channel measuring 6 mm (W) x 10 mm (H) x 30 mm (L). Computational Fluid Dynamics (CFD) simulations using Fluent model the channel's behaviour, applying a heat flux of 45,000 W/m2 at the base of the aluminium microchannel heat sink. The study examines Reynolds numbers ranging between 2000 and 2300 across inlet velocities from 0.0405 m/s to 0.04658 m/s. Prior research indicates a positive correlation between higher Reynolds numbers and improved nanofluid cooling performance. The projected conclusion based on existing literature suggests that Al2O3, with increased particle concentration, is likely to outperform other nanofluids in terms of Reynolds number. Reported viscosities of Al2O3 increase as nanoparticle concentration rises. Additionally, higher Reynolds numbers correspond to greater pressure drops in the microchannel heat sink. The investigation underscores the potential of nanofluids in improving thermal conductivity and cooling performance. The concentration-dependent behaviour of Al2O3 and its influence on Reynolds number further support its potential superiority among other nanofluids.