The Impact of Kiln Downtime on the Variable Cost Elements of Clinker Production - A Case Study

Keywords:

variable cost, downtime, heat consumption, power consumption, maintenance failure, clinker, cementAbstract

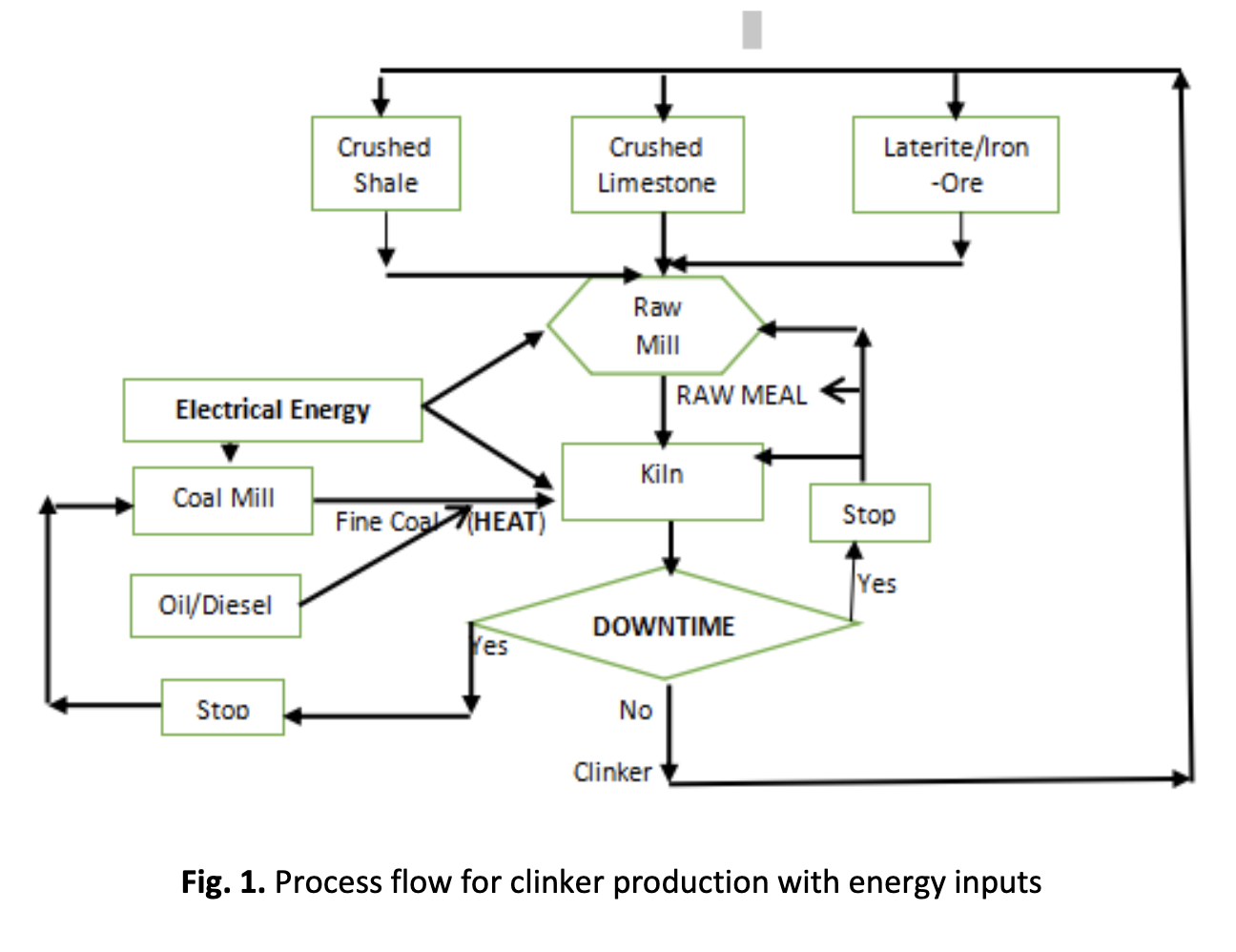

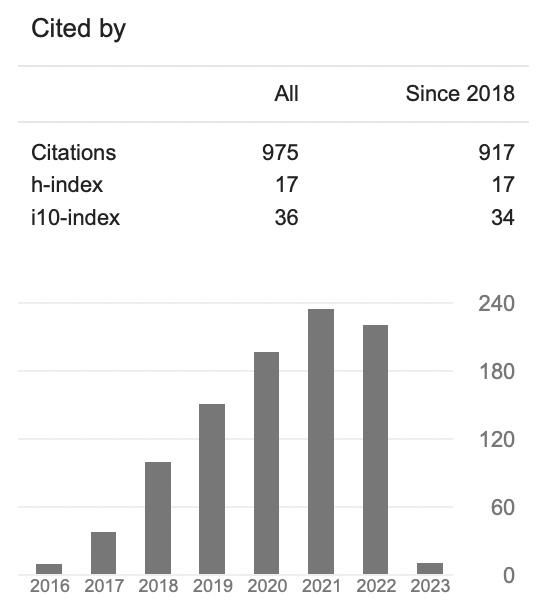

The overall cost of maintenance has been proposed by researchers as a tool for strategic decision making to identify the most economic maintenance works to be carried out. This can meet an organization’s objective to drive down the total cost of production. The review of the literature identified components that should be considered, and amongst these are the efficiency losses which arise in the cement factory under study resulting from kiln downtime. The kiln downtime days resulting from equipment failure has seen a progressive increase over the 10-year period from 2008 to 2017 in the kiln under study. There has been a parallel increase in the variable cost per ton clinker and an increase in the fixed cost per ton clinker.The efficiency losses in the kiln related to the energy consumed because of non-productive periods during cooling and subsequent re-heating are hidden under overall variable costs. Research was carried out based on the historical data from the years 2008 to 2017 to identify the relationship and impact of kiln downtime on variable cost components. The results indicate that the relationships are significant and therefore the impact of maintenance failure on efficiency losses needs to be considered in maintenance decision making.