Kaizen Event Applied to Aluminum Manufacturing – Case Study

Keywords:

Kaizen event, lean management, continuous improvement, ideas generationAbstract

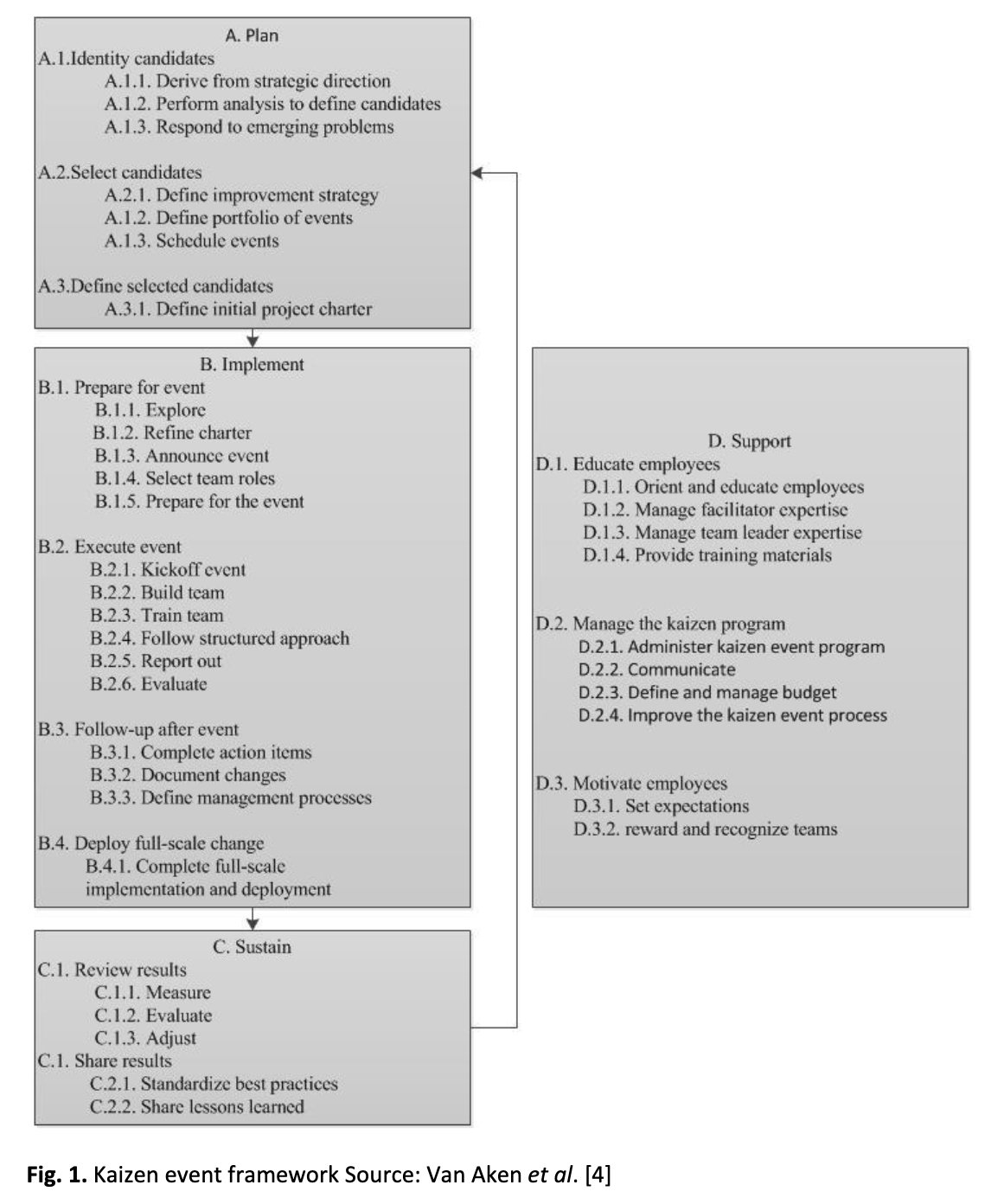

It is evident that Kaizen event adoption by both the private and public organizations elicits a wide range of positive ramifications. This is particularly in the pursuit of realization of different goals and objectives in private and public organizations. This paper explains and demonstrates how kaizen event is utilized as the powerful tool for performance enhancement through the rapid change in the targeted area, depends on Lean Manufacturing principles and techniques. Despite the abundant research information on continuous improvement tools & techniques, there is a little information related to the application of kaizen event mainly in aluminum industry due to limited academic efforts implemented for appraising or assessing the implementation of Kaizen Event approach. In this paper, Cathode sealing plant optimization has been identified as a scientific process that utilizes kaizen event to tackle contemporary issues in the plant. This paper has identified the existence of literature gap in the effectiveness of Kaizen event, particularly in the manufacturing sector. The findings in this paper has recognized that a stepwise implementation of Kaizen event leads to a reduction of rejection rates, increase in daily cathode production and maximizing the plant availability for the sake of successful & desired process.