CFD Simulation of Tesla Turbines Performance Driven by Flue Gas of Internal Combustion Engine

DOI:

https://doi.org/10.37934/aram.98.1.111Keywords:

Tesla Turbine, Combustion Engine, Flue Gas, Computational Fluid DynamicAbstract

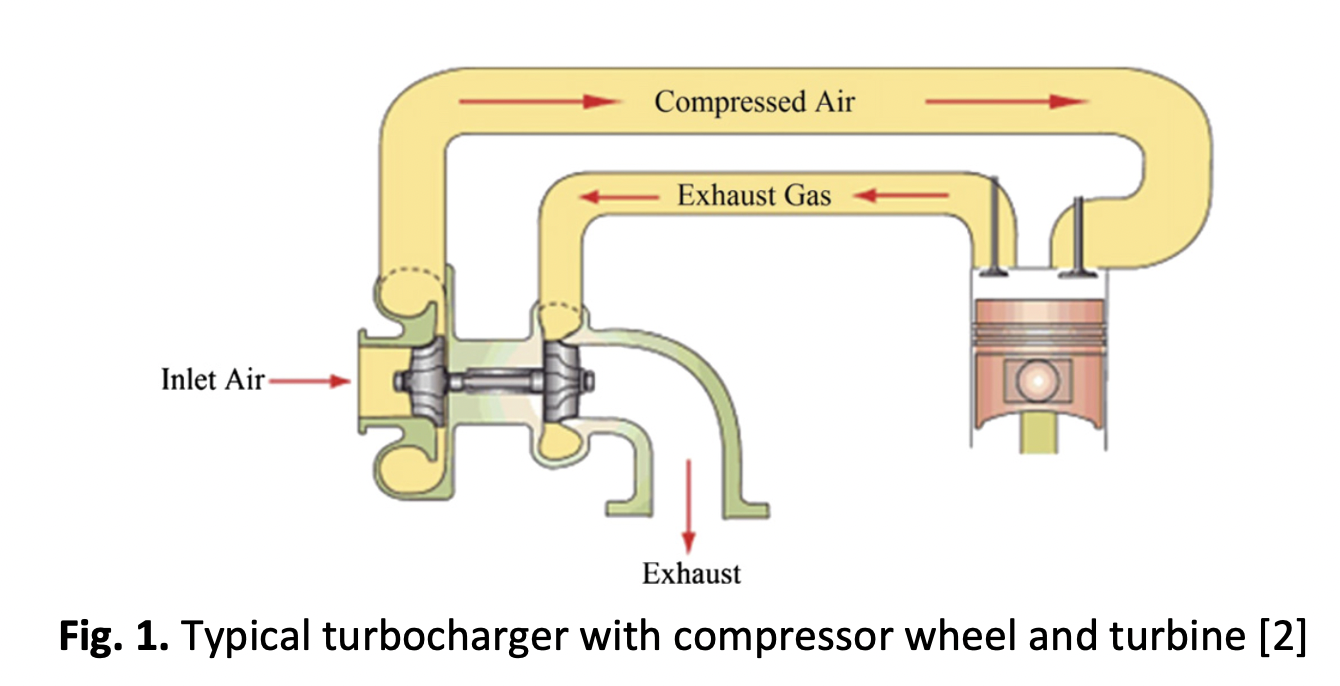

The reduced production of fossil energy, especially petroleum, has encouraged researchers to continuously increase the role of new and renewable energy as part of energy security and independence. A Tesla turbine is a device that can be used to recover wasted energy from exhaust gases, thereby increasing the overall energy use. The purpose of this study was to assess the performance of a Tesla turbine using various parameters such as engine speed, the gap between the disks, the diameter of the disks, and the number of disks. In this study, the performance of a Tesla turbine was simulated using computational fluid dynamics (CFD). The reference dimensions of this Tesla turbine are made with a slit diameter of 44 mm, a hole diameter of 10 mm, disc diameter of 140 mm, a disc width of 1.5 mm, a disc gap of 35 mm, a disc gap width of 4 mm, and a shaft length of 50 mm. The results of this study were in the form of torque and pressure drop values. In the variation of engine speed, the highest torque was at 1800 rpm with a torque value of 0.422 Nm, and the highest pressure drop was at 1800 rpm with a pressure drop value of 79161.5 Pa. In the disk gap variation, the highest torque is at a 7 mm disk gap with a torque value of 0.54 Nm and the highest pressure drop is at a 4 mm disk gap with a pressure drop value of 79161.5 Pa. In the variation of disk diameter, the highest torque was found on the disk with a diameter of 180 mm and a torque value of 0.831 Nm, and the highest pressure drop was on a disk with a diameter of 180 mm and a pressure drop value of 86753.5 Pa. In the variation of the number of disks, the highest torque was found at eight disks with a torque value of 0.765 Nm, and the highest pressure drop was found at eight disks with a pressure drop value of 82031.3 Pa. After performing this simulation, it can be concluded that at variations in engine speed, the higher the engine speed, the higher the value obtained and the variations in the disk gap, disk diameter, and number of disks. There are several values of torque that increase and decrease because the input value given cannot always increase the torque value in these variations.