The Effect of Chemical and High Pressure Homogenization Treatment Conditions on the Morphology of Nanocellulose

DOI:

https://doi.org/10.37934/aram.93.1.17Keywords:

acid hydrolysis, empty fruit bunch fibre, high pressure homogenizer, microcrystalline cellulose, nanocelluloseAbstract

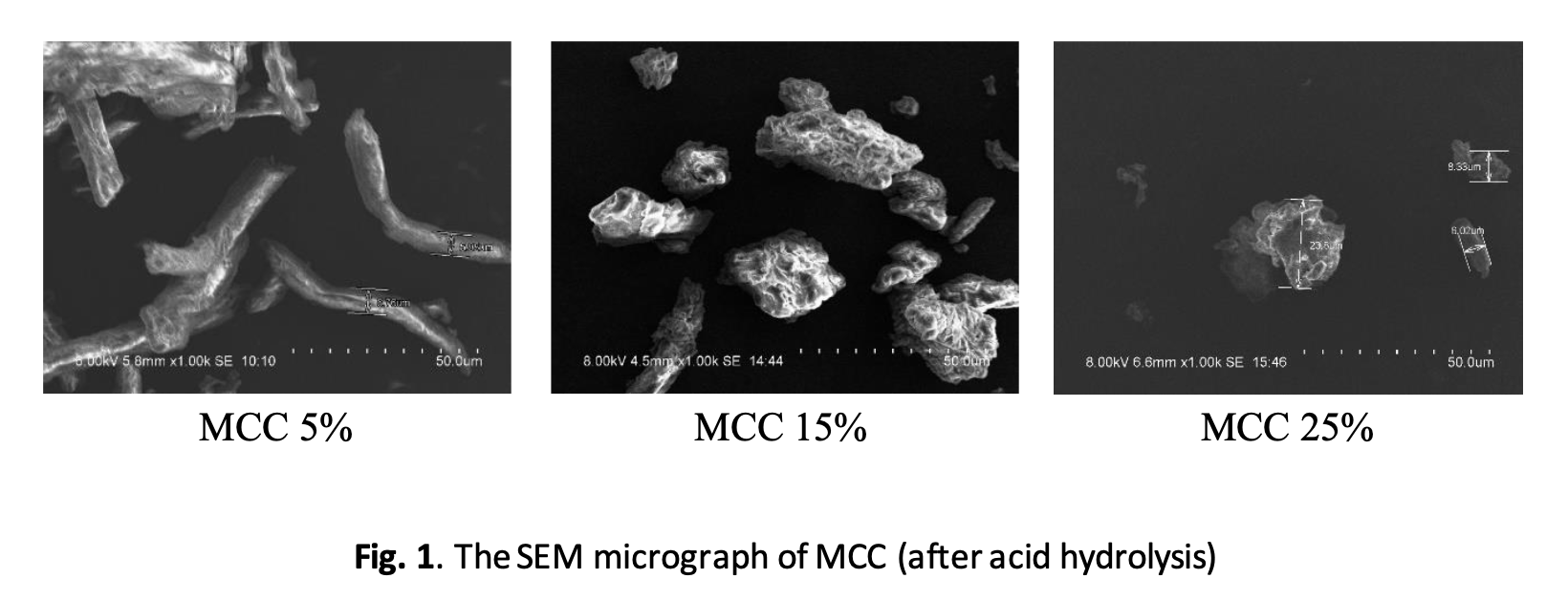

Nanocellulose was fabricated from empty fruit bunch (EFB)-derived microcrystalline cellulose (MCC) through combined acid hydrolysis with sulfuric and hydrochloric acids and high-pressure homogenization. The effects of acid-to-MCC ratio and the number of high-pressure homogenizations passes on nanoparticle morphology were investigated. The MCC was treated with different concentrations of sulphuric acid (5% to 25%) through the hydrolysis process. The diameter of the acid treated MCC fibres was reduced to roughly 8 m in Scanning Electron Microscopy (SEM) micrographs, while the length of the fibres was reduced by several microns when compared to untreated fibres. The suspensions of MCC were passed through a high pressure homogenizer at a constant pressure of 800 bar with passing times of 10, 20 and 30 cycles. After 30 cycles, the final suspension of nanocellulose (NC) became cloudy. This was a visual indication that the particles were converted to smaller sizes and were less entangled. Field Emission Scanning Electron Microscopy (FESEM) results showed that the particle size of nanocellulose ranged between 18 to 20 nm. As a result, the combination of sulphuric acid hydrolysis and high-pressure homogenization operations could be used as an efficient chemo29 mechanical technique for producing nanocellulose from various cellulosic sources.