Comparison of Preparation Methods Effect on the Stability of Compressor oil-based Nanolubricant

DOI:

https://doi.org/10.37934/aram.91.1.16Keywords:

Compressor, nanolubricant, stability, high speed homogenizerAbstract

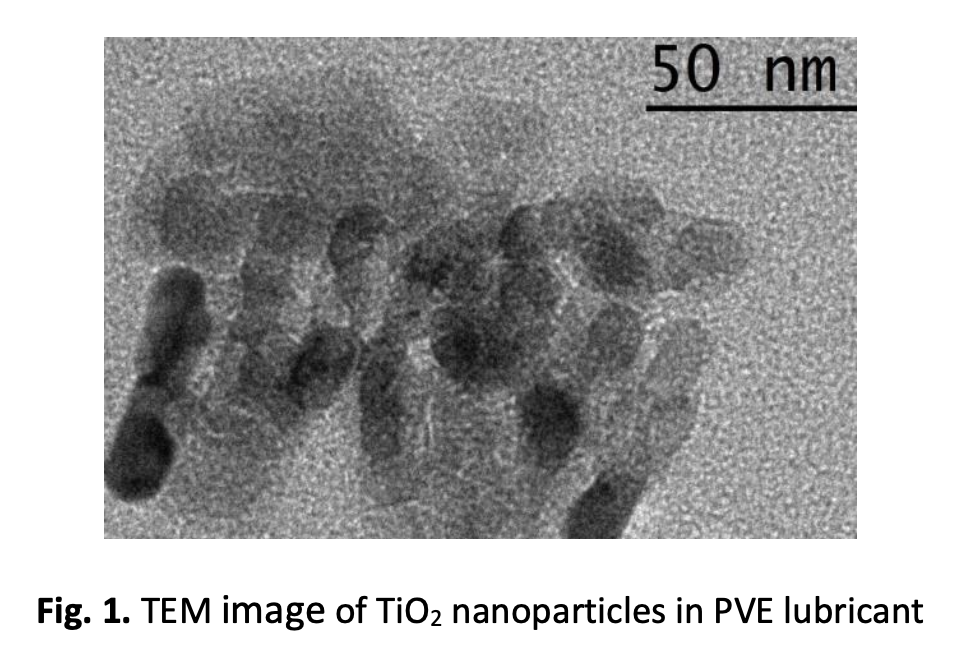

The stability evaluation for a nanolubricant is important before any application to a system. The production of nanolubricant can be done using the various method. This study aims to compare the effect of nanolubricant stability on the different preparation methods. The TiO2 nanolubricant with compressor oil base was prepared using a high-speed homogenizer (HSH) and ultrasonic bath. The HSH speed was varies between 5000 and 15000 rpm while the sonication period was varied from one hour to 5-hours. Visual observation and UV-Vis spectrophotometer method were used to evaluate the nanolubricant stability. Results reveal that the UV-Vis method produces better stability for TiO2 nanolubricant than HSH. The 5-hours ultrasonic shows the best result with a 0.9 concentration ratio after 15 days of preparation. The HSH shows that the 15000 rpm nanolubricant have better stability than the lower speed. The stability of nanolubricant increase by the increment of HSH speed as well as ultrasonication periods. The ultrasonic bath with a 5-hours sonication time is recommended for TiO2 as it provides the best stability.