Hybrid Microchannel Heat Sink with Sustainable Cooling Solutions: Experimental Analysis

DOI:

https://doi.org/10.37934/aram.89.1.16Keywords:

Micro-cooling, microchannel heat sink, rib, cavity, sustainable cooling solutionsAbstract

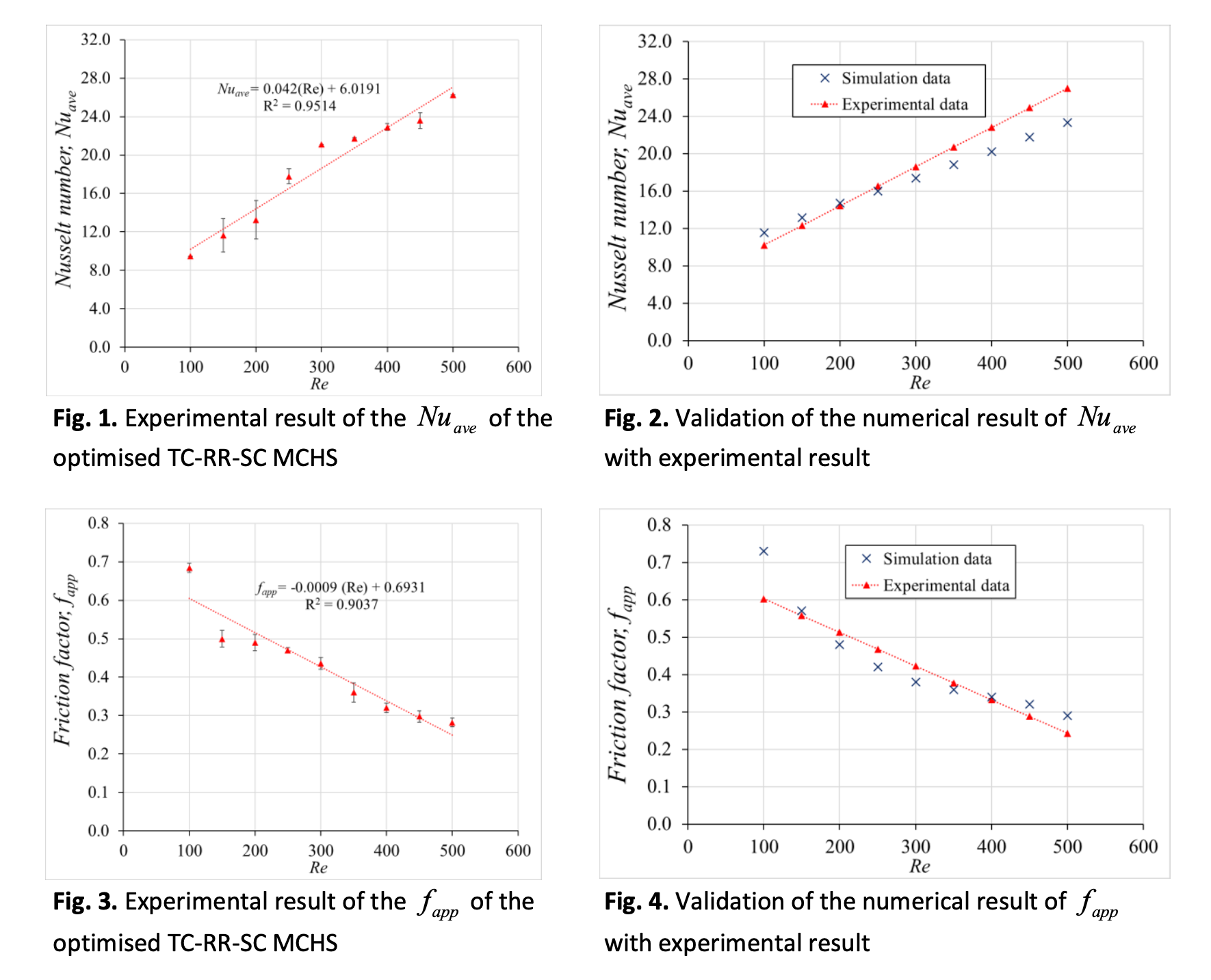

Miniaturization and utilization of low-dimensional structures of recent electronic devices have witnessed some new micro cooling methods which can fulfil the cooling demand for the electronic devices. Microchannel heat sink (MCHS) is one of the micro cooling method which appears as a promising method that can provide high heat transfer rate due to small hydraulic diameter. Furthermore, microchannel heat sink is easy to be fabricated compare to other micro cooling device. Due to fast development in electronic industry, hybrid microchannel heat sink with optimal design has received a great deal of attention in order to provide sustainable cooling solutions. However, most of the studies of hybrid microchannel heat sink only provided the numerical analysis without any validation of the proposed design experimentally. This is very important since it also will determine whether the proposed hybrid microchannel heat sink can be fabricated or not. Therefore, the aim of this article is to validate the numerical model of hybrid microchannel heat sink (TC-RR-SC MCHS) experimentally. The validation result showed that the maximum discrepancy between both simulation and experimental analyses for Nusselt number and friction factor were 15.8% and 17.4%, respectively, which is less than 20%.